XL EVAPORATIVE COOLING PRODUCTS

MAINTENANCE

S140-600 IOM (NOV 07)

Page 16

OPERATION AND MAINTENANCE SCHEDULE

EVERY 3

EVERY 6

TYPE OF SERVICE

START-UP

MONTHLY

MONTHS

MONTHS SHUTDOWN ANNUALLY

Inspect General Condition of Unit

X

X

Clean debris from unit

X

X

X

Clean and fl ush sump

X

X

X

Clean sump strainer

X

X

X

Check and adjust sump water level

X

X

Inspect heat transfer section

X

X

Inspect spray nozzles

X

X

Check and adjust fan belt tension

X

X

Check and adjust bleed rate

X

X

Check operation of make-up valve

X

X

Check unit for unusual noise or vibration

X

X

Check fan bearing locking collars

X

X

Check motor voltage current

X

X

Lubricate fan shaft bearings

X

X

X

Lubricate motor base adjusting screws

X

X

X

Lubricate the fan and pump motors

X

Check fan for rotation without obstruction

X

X

Check fan and pump motor for proper rotation

X

Drain sump and piping

X

Inspect

protective

fi

nish

X X

Lubricate capacity control and/or discharge

X

X

X

closure damper bearings and working joints

Inspect/adjust damper linkage

X

X

X

Inspect electric pan water level control

X

X

X

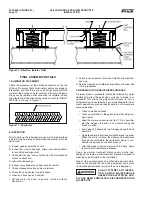

"stilling chamber"

SAFETY

Adequate precautions should be taken to safeguard the

equipment and the premises from damage and the public

from possible injury as appropriate for the installation and

location of these products.

Before performing any maintenance or inspection, make certain that all power has been

disconnected.

FREEZE PROTECTION

These products must be protected against damage and/or

reduced effectiveness due to possible freeze-up by mechani-

cal and operating methods. Please refer to the Cold Weather

Operation guidelines