XL EVAPORATIVE COOLING PRODUCTS

OPERATION

S140-600 IOM (NOV 07)

Page 11

OPERATION

Frick

®

Evaporative Condensers remove heat from the fl uid

circulating in the coil by recirculating water over the outside of

the coil and blowing air up through the wetted coil. The water

that is recirculated over the outside of the coil is stored in the

pan section at the bottom of the unit, and is pumped over the

coil through spray nozzles by the spray pump mounted on the

end of the unit. The fans are located on the side of the XLC

Centrifugal Fan Units in the dry entering air stream and are

driven by a motor that is mounted on top of the fan section.

The fans on the XLP Vane Axial Fan Units are located above

the pan in the pan/fan section in the dry entering air stream

and are driven by motors that are located below the fans.

The coolers are designed to provide maximum capacity when

both the spray system and the fans are running, and only

partial capacity when either the spray system or the fans are

running alone. A practical method of capacity control is to

cycle the fan and spray pump motors with a thermostat or

pressure switch that senses the fl uid leaving the unit. Care

must be taken, however, to cycle the fans off fi rst, then the

spray pump. This enables the solids left behind to be washed

into the pan, by the spray water, where they can be bled off

to the drain.

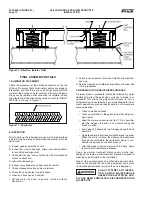

When provided, capacity control dampers are mounted

in the discharge throat of the fans on the XLC units or on

the air discharge of the XLP units for closer control of fl uid

temperature or pressure. These dampers are controlled

by a modulating damper actuator and a remote bulb-type

temperature or pressure controller. The sensing bulb of the

controller should be installed in the fl uid piping leaving the

unit, and the controller should be wired to the damper actua-

tor as shown on the appropriate wiring diagram. The damper

actuator contains an end switch that should be used to turn

off the fan motor when the dampers are fully closed.

Units provided with positive closure discharge dampers are

designed to reduce heat loss from the unit when it is not in

operation by eliminating the chimney effect. The dampers are

operated by an “On-Off” damper actuator, and are positioned

closed when the spray pump motor is off, and open when

the spray pump motor is on. The actuator should be wired

as shown on the appropriate wiring diagram.

COLD WEATHER OPERATION

Frick

®

Evaporative Condensers are suitable for most cold

weather applications when supplied with proper capacity

control and freeze protection.

A common application for Vane Axial units is to cycle the

operating fans to achieve capacity control. Typically, the fans

are cycled off as capacity drops and fi nally, the pump is shut

off. In cold weather operation, Frick

®

recommends that the

pump should be the fi rst item shut off to achieve capacity

control. By running the unit dry in cold applications, the unit’s

drive is protected from ice formation. Ice forms when the spray

water causes moist air to migrate out of idle fans where it

condenses and freezes on cold metal surfaces.

As long as the Evaporative Condensers are in operation

with a load, with capacity control dampers, the recirculating

pan water will not freeze. However, the pan water must be

protected when Evaporative Condensers are under a “no

load” condition with fans and spray pumps off. An indoor

remote sump and pump is the best means of avoiding pan

water freezing in an idle Evaporative Condenser. With this

remote sump system, the pan water is always drained to

the indoor remote sump whenever the recirculating water

pump is stopped.

Because of the Evaporative Condenser location or space

limitations, a remote sump installation may be impractical.

In such cases, supplementary heat must be supplied to the

pan water. The Evaporative Condenser will then need to be

furnished with an electric pan heater. This heater will provide

suffi cient heat to keep the spray water in the pan from freez-

ing when the unit is not running. The heater is controlled by

a thermostat that senses the pan water temperature, and is

factory set at 42°F. The heater is protected by a low water

cutout switch that prevents the heater from operating if the

pan water level is below the heater element. In addition to pro-

tecting the pan water, all exposed water piping, including the

pump suction line, pump, pump discharge piping (up to the

overfl ow connection), and the make-up water lines, should be

traced with electrical heat tape and insulated. Some Evapo-

rative Condenser installations will permit all spray water to

be drained from the pan during cold weather operation. This

permits dry operation of the Evaporative Cooler or Condenser

when the load and ambient temperatures are low.

Units that require year-round operation in a freezing climate

should be equipped with an electric pan water level control

package. This package ensures a constant water level with-

out adjustment and also maintains very close control of the

pan water level. The system consists of a weather-protected

electric fl oat switch with stilling chamber mounted on the pan

section and a weather-protected solenoid valve mounted on

the water makeup connection. When this system is used, it

replaces the standard mechanical water makeup valve.