XL EVAPORATIVE COOLING PRODUCTS

INSTALLATION

S140-600 IOM (NOV 07)

Page 10

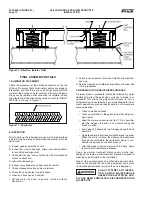

Figure 10 - Vibration Isolator Rails

FINAL ASSEMBLY DETAILS

1. ELIMINATOR PLACEMENT

Check the placement of the eliminator sections on the top

of the unit to ensure that all eliminator sections are properly

interlocked and that there are no openings present which

will allow the escape of water droplets. Eliminator tie-down

straps can be removed after assembly is complete. Check

the orientation of the eliminator sections to ensure "RIGHT

SIDE UP" as shown in Figure 11.

2. INSPECTION

Prior to start-up, the following services, which are described

in detail in the operating and maintenance manual, must be

performed:

A. Inspect general condition of unit.

B. Inspect fan, motors, bearings, drives, and locking collars

for condition and alignment.

C. Check belt tension and condition per the maintenance

manual instructions.

D. Lubricate all bearings.

E. Inspect spray headers and heat transfer section.

F. Check makeup valve and sump water level.

G. Check fans and guards for obstructions.

H. Clean and fl ush pan and strainer.

I. Rotate fan(s) by hand to ensure rotation without

obstruction.

J. Check fans and pumps for correct rotation and electrical

hook-up.

K. See the Operation and Maintenance Manual for new belt

run-in procedures.

3. BREAKING IN THE GALVANIZED SURFACES

A proper break-in procedure should be followed for water

treatment to allow the galvanized surfaces to break in or

passivate. This allows the galvanized surfaces to form a

self-protecting zinc carbonate layer. A qualifi ed water treat-

ment specialist can provide specifi c details, but following are

some guidelines.

• Clean all wetted surfaces.

• Touch up scratches in the galvanizing with cold galva-

nized paint.

• Keep the water as close neutral (pH 7.0) as possible.

Must be between 6.5 and 7.5 at all times during the

break-in period.

• Avoid cleaning chemicals in pH ranges above 8.0 and

below 6.0.

• Operate under minimal load during the break-in period.

When the unit is installed, the water can be circulated

through the unit before the refrigerant piping is con-

nected to begin the passivation process.

• After the break-in period, typically 30-45 days, begin

regular water treatment procedures.

Again, local water treatment professionals will be best

equipped to create a water treatment program designed to

meet the specifi c needs of the installation.

Proper start-up procedures and scheduled periodic main-

tenance will prolong the life of the equipment and ensure

trouble-free performance for which the unit is designed.

DO NOT ATTEMPT ANY INSPEC-

TION AND/OR MAINTENANCE

UNLESS THE ELECTRICAL SUP-

PLY HAS BEEN COMPLETELY DISCONNECTED AND

LOCKED OUT.

Figure 11 - Eliminator