VYPER

™

VARIABLE SPEED DRIVE

INSTALLATION - OPERATION - MAINTENANCE

S100-200 IOM (MAY 08)

Page 2

Indicates an imminently hazardous situation which, if not avoided, will result in death or serious

injury.

Indicates a potentially hazardous situation or practice which, if not avoided, will result in death

or serious injury.

SAFETY PRECAUTION DEFINITIONS

Indicates a potentially hazardous situation or practice which, if not avoided, will result in dam-

age to equipment and/or minor injury.

NOTE:

Indicates an operating procedure, practice, etc., or portion thereof which is essential to highlight.

Contents

PREFACE ..........................................................................3

JOB INSPECTION .............................................................3

TRANSIT DAMAGE CLAIMS ............................................3

UNIT IDENTIFICATION .....................................................3

INSTALLATION .................................................................4

FOUNDATION ..................................................................4

RIGGING AND HANDLING ...............................................4

FRICK VYPER

™

MODELNUMBER DEFINITIONS ...........4

GENERAL DESCRIPTION ................................................5

ELECTRICAL LIMITS ........................................................5

CURRENT LIMITS ............................................................5

INPUT SHORT CIRCUIT LIMITS ......................................5

ENVIRONMENT ................................................................5

COOLANT TEMPERATURE LIMITS .................................6

HEAT EXCHANGER PRESSURE DROP .........................7

POWER WIRING ...............................................................8

GROUNDING ....................................................................8

FUSES AND CIRCUIT BREAKERS ..................................8

ACCEPTABLE CABLE TYPES ..........................................8

CONTROL WIRING ...........................................................8

TRANSFORMERS ............................................................9

POWER FACTOR CAPACITORS ......................................9

SOFT-START SEQUENCE ................................................9

INTERFACING ELECTRICAL EQUIPMENT .....................9

INTERFERENCE WITH ELECTRONICEQUIPMENT .......9

SYSTEM OPERATING CONDITIONS ............................10

PNEUMATIC CONTROLS ...............................................10

VYPER

™

SYSTEM OVERVIEW ......................................10

CONFIGURATION: ..........................................................14

VYPER

™

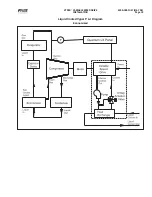

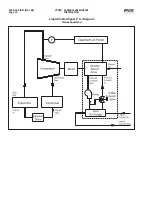

COOLING LOOP ..............................................14

Liquid Cooled Vyper P & I Diagram-Economized ............15

Liquid Cooled Vyper P & I Diagram-Noneconomized ......16

PACKAGE-MOUNTED VYPER

™

.....................................17

VYPER

™

PREINSTALLATION SITE CHECKLIST ...........18

BLOWER MOTOR ROTATION ........................................18

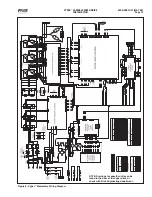

POWER AND CONTROL WIRING ENTRY LOCATIONS 19

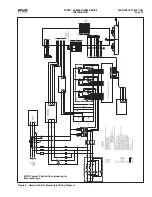

EXTERNAL POWER AND CONTROL WIRING ..............20

ELECTRICAL CONDUITS ...............................................21

WIRING DIAGRAM OPTIONS ........................................21

MOTOR Thermistor PROTECTION .................................21

MOTOR RTD THERMAL PROTECTION ........................22

TEMPERATURE CONTROL VALVE WIRING .................22

MOTOR COOLING BLOWER WIRING ...........................23

DRAWING NOTES ..........................................................23

ANALOG BOARD WIRING ..............................................24

QUANTUM

™

LX COMMUNICATIONS WIRING ................25

INSTALLATION CHECK LIST ..........................................25

THREE INSTALLATION STEPS ......................................26

COOLANT REPLACEMENT ...........................................26

OPERATION ...................................................................28

QUANTUM

™

LX CONTROL PANEL .................................28

VYPER

™

OPERATION ....................................................28

QUANTUM

™

LX PANEL SET UP ......................................32

ACCESSING THE VYPER

™

SETUP ...............................32

SETTING THE USER LEVEL ..........................................33

PROGRAMMING .............................................................34

VYPER

™

/ QUANTUM

™

LX COMMUNICATIONS .............34

PID SETUP ......................................................................35

SETTING THE MOTOR SCREEN ...................................36

VFD and Capacity Control Settings .................................39

SETTING THE JOB FLA .................................................44

Tables C and D: Job FLA Calculation ..............................44

FRICK INTERFACE BOARDDIP SWITCH SETTINGS ...45

MAINTENANCE ..............................................................47

STANDARD MAINTENANCE ........................................47

REPLACEMENT OF THE VYPER

™

POWER MODULE ...47

REPLACEMENT OF THE VYPER

™

HARMONIC FILTER

MODULE .........................................................................48

FREQUENTLY ASKED QUESTIONS ..............................48

ADDENDUM ....................................................................49

VYPER

™

ALARMS / SHUTDOWNS ................................49

FAULT CODE DESCRIPTIONS .......................................49

FRICK VYPER

™

FAULT CODES .....................................50