8

ZZ1027/3

13

130mm

Heater

Deflector

Plate

Fig. 3

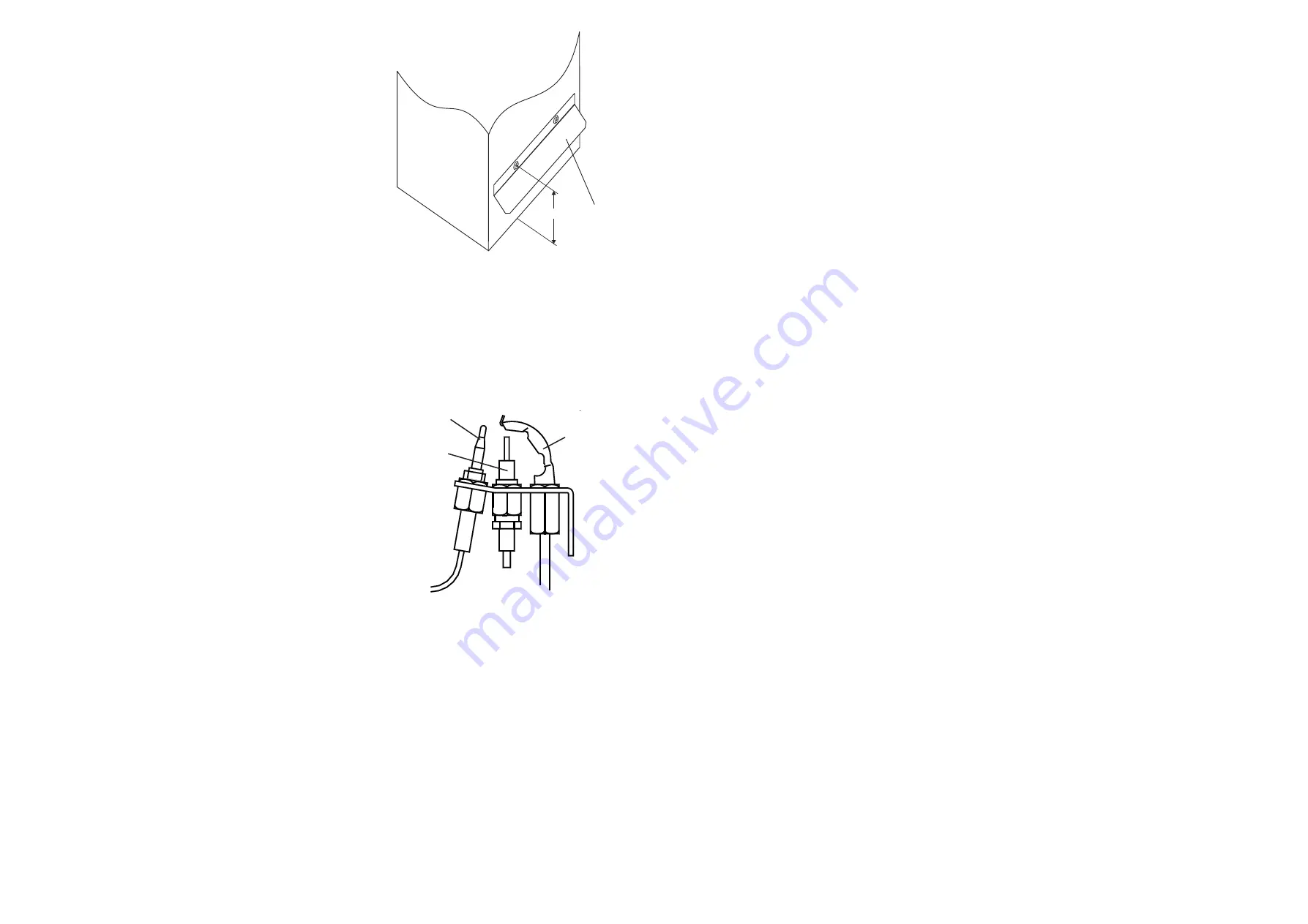

Deflector Plate

Thermocouple

Pilot Burner

Electrode

Fig. 4

Pilot Burner Assembly

6.3

IGNITION OF PILOT AND MAIN BURNERS:

WARNING:

If the Pilot Burner is extinguished either intentionally or

unintentionally, no attempt should be made to relight the gas for a minimum of 3

minutes. Ensure that the Electrical supply, time control and Selector switches

are set to ‘

OFF

’

.

6.3.1

Set the room thermostat to its lowest or

OFF

setting.

6.3.2

On the Multifunctional Control, remove the Outlet Pressure test

point cover, and a fit pressure test gauge (refer Fig. 5)..

6.3.3

Turn the heater Gas supply

ON

, test for gas soundness and

purge the whole gas pipe as described in BS 6891.

6.3.4

Referring to Fig .5, press and hold the OPERATING CONTROL,

and whilst observing the Pilot Burner, repeatedly press the Piezo

igniter button until the Pilot Burner ignites.

6.3.5

After 20 seconds release the OPERATING CONTROL and let it

spring out; ensure that the Pilot Burner remains alight. If the Pilot

Burner extinguishes, rotate the OPERATING CONTROL clockwise

to the ‘l’ position and ensure that the OPERATING CONTROL is

fully reset. Wait three minutes and repeat steps 6.3.4 and 6.3.5

until the Pilot Burner remains alight.

6.3.6

Ensure that the pilot flame envelops the thermocouple tip, adjusting the Pilot Adjuster as required (Refer Figs. 4 and

5).

6.3.7

Set the Heater Electricity supply ON.

6.3.8

Set the Time Control to the required Heating On periods.

6.3.9

Set the Selector switch to ‘TIMED’.

6.3.10 Set the room thermostat to MAXIMUM.

6.3.11 Ensure that the Main Burner has now ignited.

6.3.12 Test for gas leakage at the supply, Multifunctional Control, and

Pilot and Main Burners using a proprietary detection fluid, sealing

any leaks found.

6.3.13 Allow the heater to operate for a minimum of 15 minutes to ensure

stability.

6.4

MAIN BURNER PRESSURE TEST:

IMPORTANT: AIR HEATER BURNERS ARE FACTORY SET TO PROVIDE A

NOMINAL RATE OUTPUT AS DETAILED IN SUB PARA 1.2

6.4.1

Referring to Table 4 and Fig. 4 below, ensure that the pressure test

gauge indicates the correct burner pressure.

6.5

EXTINGUISHING OF PILOT AND MAIN BURNERS:

6.5.1

On the Multifunctional Control, rotate the OPERATING CONTROL

clockwise to the ‘l’ position and ensure that the OPERATING CONTROL fully resets, and both Pilot and Main

Burners are extinguished.

6.5.2

On the Multifunctional Control, remove the pressure test gauge and refit the Outlet Pressure test point cover, and

test for gas soundness.

6.6

TEMPERATURE RISE CHECK:

6.6.1

Ignite the Pilot and Main Burners and allow to operate for 15 minutes to ensure stability.

6.6.2

With the Main Burner operating continually, check that the temperature rise across the heater is between 45

O

C -55

O

C,

setting the fan speed accordingly, (decrease the fan speed to increase the temperature rise). The fan speed is

adjusted by selecting the fan speed at the electrical control panel (decrease voltage selection to decrease fan speed).

Note: TAPPING 1 = 150V, TAPPING 2 = 170V,

TAPPING 3 = 190V,

TAPPING 4 = 210V,

TAPPING 5 = 230V.

8.9.6

Disconnect 2 x TTB connections.

8.9.7

Disconnect the Multifunctional Control connections.

8.9.8

Release 4 x 4mm screws securing the Electrical Assembly to the heater cabinet and remove the Electrical Assembly,

releasing wiring from cable clamps and grommets as required..

8.9.9

Refitting or replacement is in reverse order.

8.10

TIME CONTROL REMOVAL:

8.10.1 Ensure that the electrical supply is isolated.

8.10.2 Release the securing screw situated on the lower face of the Time Control and remove it by partially withdrawing

bottom of the Time Control and then lifting upwards.

8.10.3 Disconnect the Time Control electrical connections from its integral terminal strip.

8.10.4 Refitting or replacement is in reverse order.

8.10.5 Set the Time Control to the required ON and OFF times.

8.10.6 Set the Time Control to the correct time.

8.11

FAN DELAY CONTROL AND LIMIT SWITCH REMOVAL:

8.11.1 Ensure that the electrical supply is isolated.

8.11.2 Remove the appliance lower and upper doors.

8.11.3 Release 2 x 4mm screws securing the Limit Switch cover and withdraw the cover.

8.11.4 Disconnect the required control/switch.

8.11.5 Release 2 x securing screws and remove the required control/switch.

8.11.6 Refitting or replacement is in reverse order.

8.12

SPILLAGE MONITOR DEVICE (TTB) REMOVAL:

8.12.1 Ensure that the electrical supply is isolated.

8.12.2 Remove the appliance lower and upper doors.

8.12.3 Remove the Air Circulation fan as detailed in para 8.8.

8.12.4 Cover the aperture to the heat exchanger in the top shelf to prevent objects falling into the heat exchanger.

8.12.5 Release and remove 6 x screws securing the fan compartment rear access panel, and withdraw the panel.

8.12.6 Disconnect the TTB terminal block plug from the terminal block socket, situated on the compartment rear bulkhead,

remove the grommet rearwards and pass the terminal block through the aperture in the rear bulkhead.

8.12.7 Release and remove the 5mm nut and lock washer securing the TTB Assembly to the Draught Diverter, and withdraw

the TTB Assembly.

8.12.8 Refitting or replacement is in reverse order.

8.13

HEAT EXCHANGER ACCESS:

8.13.1 Release 2 x securing screws and remove heat exchanger access caps and gaskets.

8.13.2 Remove the heat exchanger baffles.

8.13.3 Reassembly is in reverse order.

NOTE: When reassembling, ensure that the baffles are pushed fully home and that the access caps are fully sealed. In the event of

heat exchanger replacement being necessary, contact Johnson and Starley Service Department.

9.

DEFECT DIAGNOSIS

9.1

IMPORTANT: If an electrical defect occurs after installation of the appliance; preliminary earth continuity, polarity, and

resistance to earth checks should be carried out with a multimeter. On completion of anymaintenance/fault-finding task

that has required the breaking and remaking of electrical connections, then checks of continuity, polarity, and resistance to

earth must be repeated.

9.2

WARNINGS:

9.2.1

When purging or checking gas supplies, ensure that the ventilation to the room or cupboard is adequate, and that all

naked lights are extinguished.