9629 Microprocessor Controller

- 32 -

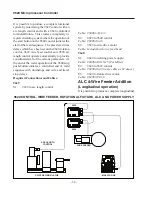

C. Interconnections

The 9629 control can be connected to other

devices to as part of a complete welding sys-

tem. Standard length cables, complete with the

appropriate Amphenol connectors are available

from Jetline. Special length cables can be made

to order.

The example illustrated below shows the sim-

plest application. In this case the 9629 control

is connected to the wire feed drive unit as a

stand-alone product.

The control is shown also connected to a Miller

Maxstar DX power supply. This is necessary if

the 9629 control is fitted with the pulse option

and it is desired to synchronize the pulsing of the

wire with the pulsing of the weld current.

Note: The Miller range of TIG welding power

supplies are available with a special 10-pin

connector, this permits easy communication

between the 9629 and the power supply. Power

supplies from other manufacturers can be used,

if so, consult Jetline for details of interconnec-

tion cables and required interfaces.

Required Connections and Cables

:

S1: Unused

S2:

9629 to welding power supply.

Cable: 9600S2-DX10-15 (For Miller)

S3:

9629 to wire drive motor

Cable: Included with wire feed head

9629 CONTROL, WIRE FEEDER AND POWER SUPPLY

9629

MAXSTAR DX

WIRE FEEDER

Summary of Contents for 9600 Series

Page 2: ...9629 Microprocessor Controller 2...

Page 6: ...9629 Microprocessor Controller 6...

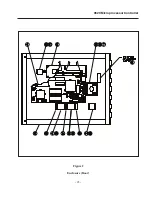

Page 41: ...9629 Microprocessor Controller 41 Figure 1 Enclosure SUB PANEL GROUND MAIN GROUND...

Page 43: ...9629 Microprocessor Controller 43 Figure 2 Enclosure Door...

Page 49: ...9629 Microprocessor Controller 49 S1 CONNECTOR...

Page 50: ...9629 Microprocessor Controller 50 S2 CONNECTOR...

Page 51: ...9629 Microprocessor Controller 51 S3 CONNECTOR...

Page 52: ...9629 Microprocessor Controller 52...

Page 53: ...9629 Microprocessor Controller 53 Interconnection Diagram...