17

9.11

Setting blade speed

1. Turn

machine

OFF.

2. Turn lever (Figure 23) to desired setting:

#1 – 145 sfpm

#2 – 200 sfpm

#3 – 245 sfpm

Do not change blade speed

during cutting operation.

Figure 23

Material chips or shavings are the best indicator of

proper blade speed and downfeed rate. See

section 11.4, Evaluating cutting efficiency.

9.12

Blade guide adjustment

1. Loosen knobs (A, Figure 24).

2. Slide guide assemblies as close to workpiece

as possible, without interfering with the cut.

This will prevent excessive blade exposure,

and deflection of blade during cutting.

3. Retighten

knobs.

Figure 24

The guide bearings come pre-adjusted from the

factory, but should be inspected frequently and

adjustments made as needed.

For most efficient operation and maximum

accuracy, provide 0.001” clearance between the

blade and the guide bearings. The bearings will still

turn freely with this clearance. If the clearance is

incorrect, the blade may track off the drive wheel.

1. Disconnect machine from power source.

2. Raise bow to vertical and secure in place by

turning off hydraulic cylinder.

3. Loosen socket head cap screw (B, Figure 25)

and adjust guide assembly until back roller

bearing (C) is slightly contacting back edge of

blade.

4. Loosen nut (D) and rotate eccentric shaft (E)

to adjust side bearing until bearing just

touches side of blade. Do not pinch the blade.

5. Blade should still move up and down freely

when grasped as in Figure 26. Make sure

blade teeth do not interfere with guide

bearings.

Make sure power is

disconnected and hands are protected

before handling blade.

6. Tighten

nut

(C).

7. Repeat for other blade guide assembly.

Figure 25

Figure 26

9.13

Chip brush

The chip brush (B, Figure 19) must be properly

adjusted and maintained in working condition;

otherwise damage to blade can occur. Adjust the

brush so that its bristles overlap the blade.

Replace brush if it becomes worn or damaged.

Summary of Contents for HVBS-710G

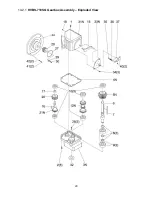

Page 23: ...23 14 1 1 HVBS 710SG Table and Stand Assembly Exploded View...

Page 24: ...24 14 1 2 HVBS 710SG Bow Assembly Exploded View...

Page 29: ...29 14 2 1 HVBS 710SG Gearbox Assembly Exploded View...

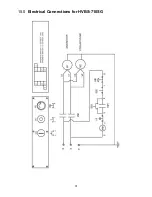

Page 31: ...31 15 0 Electrical Connections for HVBS 710SG...

Page 32: ...32 427 New Sanford Road LaVergne Tennessee 37086 Phone 800 274 6848 www jettools com...