17

6. Maintenance

Easy and low-cost routine maintenance can ensure the lift work normally and safely. Following are requirements for routine

maintenance. You may decide

the frequency of routine maintenance by consulting your lift’s working conditions and time.

THE FOLLOWING PARTS NEED TO BE LUBRICATED

6.1 Daily checking items before operation

The user must perform daily check. Daily check of safety latch system is very important

– the discovery of device failure before

action could save your time and prevent you from great loss, injury, or casualty.

·Before operation, judge whether the safety latches are engaged by sound.

·Check whether oil hose well connected and whether it leaks or not.

·Check the connections of chain and steel cable and check the power unit.

·Check whether plug bolts firmly screwed.

·Check if safety teeth and safety block matched well or not.

6.2 Weekly checking items

·Check the flexibility of moving parts.

·Check the working conditions of safety parts.

·Check the amount of oil left in the oil tank. Oil is enough if the carriage can be raised to highest position. Otherwise, oil is

insufficient.

·Check whether plug bolts firmly screwed.

6.3 Monthly checking items

·Check whether plug bolts firmly screwed.

·Check the tightness of the hydraulic system and screw firm the joints if it leaks.

·Check the lubrication and abrasion circumstance of axial pins, carriages, lifting arms and other related parts and replace in time

with new ones if they failed to work well.

·Check the lubrication and abrasion circumstance of steel cable.

6.4 Yearly checking items

·Empty the oil tank and check the quality of hydraulic oil.

·Wash and clean the oil filter.

If users strictly follow the above maintenance requirements, the lift will keep in a good working condition and meanwhile

accidents could be avoided to a large extent.

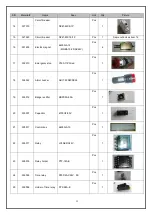

S/N

Name

1

Slider

2

Steel cable

3

Side slider

4

Sliding wheel

5

Safety block A1(A2)

6

Safety block B1(B2)

7

Spring

8

Shaft

Summary of Contents for JA5500F

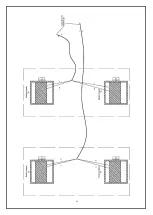

Page 19: ...19 Annex2 Overall diagram...

Page 20: ...20 Annex3 Floor plan Annex 4 Steel cable connection...

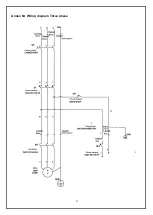

Page 22: ...22 Annex 6 Wiring diagram Three phase...

Page 23: ...23 Electric wire connections in control box Picture of the control box and connections...

Page 24: ...24...

Page 25: ...25...

Page 26: ...26...

Page 27: ...27 Annex7 Separate diagrams for the lift JA5500F...

Page 35: ...35 Annex9 Size and weight requirements on vehicles...

Page 36: ...36...