Chapter 2

Safety Instructions

ITW Dynatec

UFD Applicator, Manual 40-43, Rev. 6.16

Page 11

Explosion/ Fire Hazard

1. Never operate this unit in an explosive environment.

2. Use cleaning compounds recommended by ITW Dynatec or your adhesive supplier

only.

3. Flash points of cleaning compounds vary according to their composition, so consult

with your supplier to determine the maximum heating temperatures and safety

precautions.

Use of PUR (Polyurethane) Adhesives

1. PUR adhesives emit fumes (MDI and TDI) that can be dangerous to anyone exposed

to them. These fumes cannot be detected by the sense of smell. ITW Dynatec strongly

recommends that a power

‐

vented exhaust hood or system be installed over any PUR

system.

2. Consult with your adhesive manufacturer for specifics about required ventilation.

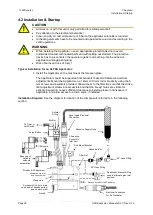

CAUTION

Because of the nature of PUR adhesives to strongly bond in the presence of moisture,

care must be taken to prevent them from curing inside ITW Dynatec equipment.

If PUR adhesive solidifies in a unit, the unit must be replaced. Always purge old PUR

adhesive from the system per your adhesive manufacturer's instructions and time table.

ALLOWING PUR ADHESIVE TO CURE IN A UNIT OR ITS COMPONENTS VOIDS ITW

DYNATEC'S WARRANTY.

Eye Protection & Protective Clothing

WARNING

EYE PROTECTION & PROTECTIVE CLOTHING REQUIRED

1. It is very important that you PROTECT YOUR EYES when working around

hot melt adhesive equipment!

2. Wear a face shield conforming to ANSI Z87.1 or safety glasses with side

shields which conform to ANSI Z87.1 or EN166.

3. Failure to wear a face shield or safety glasses could result in severe eye injury.

4. It is important to protect yourself from potential burns when working around hot melt

adhesive equipment.

5. Wear heat-resistant protective gloves and long

‐

sleeved, protective clothing to prevent

burns that could result from contact with hot material or hot components.

6. Always wear steel

‐

reinforced safety shoes.