ITW Dynatec

Chapter 5

Maintenance and Repair Notes

Page 44

UFD Applicator, Manual 40-43, Rev. 6.16

Testing Resistance of the RTD Temperature Sensor

(Options D, M, N and P in Chapter Model Designation Guide)

WARNING

Heed all security advices given in Chapter 5.1.

Maintenance and repair work is only permitted for skilled personnel!

1. Stop all motors.

2. Turn the ASU OFF or disable the Applicator and preheater zones at the control panel.

Disconnect all electrical cables from the Applicator.

3. Relieve the adhesive pressure by following the instructions under Chapter 5.4

“Relieving Adhesive Pressure”.

4. Unplug the electrical cable from the adhesive supply hose or extension cable to

expose the pins in the cable.

Note: The resistance value (Ohms) of the temperature sensor depends on the

temperature of the sensor at the time it is being tested. All values listed in the table

below are given at 25°C (77°F). To correct for ambient temperatures other than 25°C

(77°F), see next Chapter “Resistance Tables, Temperature sensors” for complete

resistance-temperature tables for the RTD sensors.

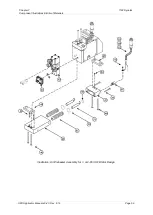

5. Using the schematics in Chapter 9 as a reference, measure the resistance of the

sensor and compare to the values in the table below. A tolerance of ± 5% is allowed

for ambient temperature differences. A sensor that tests outside of this range must be

replaced.

Applicator Control

Sensor Resistance

at 25°C (77°F)

DynaControl (option D)

110 ohms

MCV Control (option M)

110 ohms

Upgrade (Ni, option N)

138 ohms

Allen-Bradley (option D)

110 ohms

Upgrade (Pt, option P)

110 ohms

Testing the J-type Thermocouple Temperature Sensor

(Control option L in Chapter Model Designation Guide)

WARNING

Heed all security advices given in Chapter 5.1.

Maintenance and repair work is only permitted for skilled personnel!

1. Stop all motors.

2. Turn the ASU OFF or disable the Applicator and preheater zones at the control panel.

Disconnect all electrical cables from the Applicator.

3. Relieve the adhesive pressure by following the instructions under Chapter 5.4

“Relieving Adhesive Pressure”.

4. Unplug the electrical cable from the adhesive supply hose or extension cable to

expose the pins in the cable.

5. Using the schematics in Chapter 9 as a reference, first measure the resistance across

the thermocouple leads to check for an open junction. The resistance should be zero