ITW Dynatec

Chapter 4

Installation & Startup

Page 28

UFD Applicator, Manual 40-43, Rev. 6.16

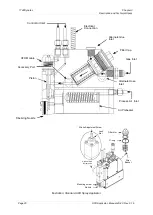

5. Make the electrical connection from the hose to the applicator by connecting the

female connector of the hose to the male connector of the applicator.

6. Connect the spray air line to the preheater using the adapter provided. Do not

overtighten the compression fitting, or the air line could collapse, reducing air flow.

7. Make the electrical connection from the extension cable to the preheater by

connecting the female connector of the cable to the male connector of the preheater

8. It is advisable to check the temperature of the applicator. This can be done through

the temperature readout of the adhesive supply unit. Surface temperature may be

checked with a separate pyrometer and surface probe or with a dial thermometer.

Turn the system power switch ON. Permit the applicator to warm up at least 15

minutes (5 minutes for module change) before reading temperature.

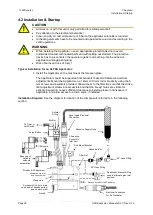

9. Purge the Applicator of air and oil. Turn the Applicator ON electrically and

pneumatically.

WARNING! HIGH PRESSURE! HOT ADHESIVE!

During the purging procedure, hot adhesive and oil can come out of

the Applicator under high pressure. Wear safety glasses, gloves and

protective clothing.

Use a stable, deep container to collect hot-melt adhesive and/ or oil.

Remove the nozzle from the module. Place a heat resistant container under the

module to collect the material that drains from the Applicator. Manually open the

solenoid by pushing (with a small screwdriver or other tool) the purge button located

on the solenoid coil. Continue to hold in the purge button until all air and oil have

drained and only adhesive flows from the module.

10. Replace the nozzle, orienting the nozzle tip so it points toward the substrate.

11. Interconnect the components with the foreseen Profibus (or EtherNet, etc.) interface

cables (if applicable).

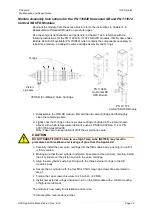

Daily operation

Purge the Applicator before every start of production respectively of a shift by allowing

the adhesive flows out until it is satisfactory.

Then switch off the adhesive and clean the nozzle from adhesive.

Bring the Applicator in work position and continue production.