Chapter 4

Installation & Startup

ITW Dynatec

UFD Applicator, Manual 40-43, Rev. 6.16

Page 25

Chapter 4

Installation & Startup

CAUTION

•

Before setting up, please read this documentation carefully.

•

Pay attention to all the installation and connecting advices.

•

Heed all safety instructions mentioned in Chapter 2.

4.1 Conditions for set-up and mounting

Place requirement

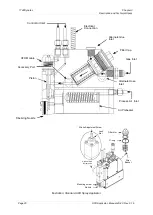

Install the Applicator in the machine so that the operator is able to work on it from all

sides, for e.g. for adjusting, preparing, maintaining, repairing, cleaning, etc. See drawing

of the unit for admeasurements.

Mounting and alignment

•

The complete unit has to be set up on solid, stable and flat ground.

•

The alignment in height of the complete system has to be considered.

•

The alignment of the machine has to be considered.

Electrical connection

•

Necessary electrical connection has to be provided. See electrical schematics.

•

Never connect or disconnect plug-and-socket connections under load!

•

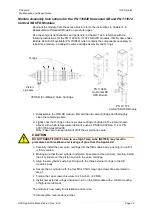

The service block’s incoming electrical power and temperature control is supplied

through the flexible cable exiting the adhesive supply hose cuff or through an

extension cable from the ASU. The Applicator has a circular, plastic connector which

mates with the connector attached to this cable.

•

Incoming power and temperature control for the air preheater, if applicable, is supplied

by a cable extension from the ASU.

Pneumatic connection

•

In any case the air has to be clean and dry! See advice in Chapter 4.3 “Quality of

compressed air”.

•

Please heed that units with high air demand may not be used at the same time with

the same air supply.

•

Incoming module-activation air is supplied through a solenoid valve. It must be clean

and unlubricated.

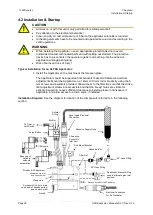

For conventional modules

(module option H, V, HQ or VQ in the model number (see

previous pages), the module activation air is controlled by a four-way solenoid valve

and should be separately regulated and maintained at a pressure between 4.1 to 6.9

bar (60 to 100 psi). Air lines from the solenoid valve should be 6.4mm (1/4 inch).

Head air inlet ports are G 1/8 threads (1/8 NPT).

For snuffback modules

(all other module options), the module activation air is

controlled by a either a four-way or a five-way solenoid valve. See Appendix A and B

for details on the solenoid setup.

•

Incoming process (preheater) air must be supplied through a pressure regulator. The

air must be clean and unlubricated. Operating pressure depends on the choice of

nozzle. The Applicator’s air supply line must be at least 1/4” O.D. For the UFD 150

applicator, 3/8” O.D. airline is recommended.

Advices:

•

Check all screw connections at the unit and retighten if necessary.

•

Lay the cables and heated hoses so that no risk or least possible risk of stumbling

occurs.