Console user manual

18

01 - 10 - 2004

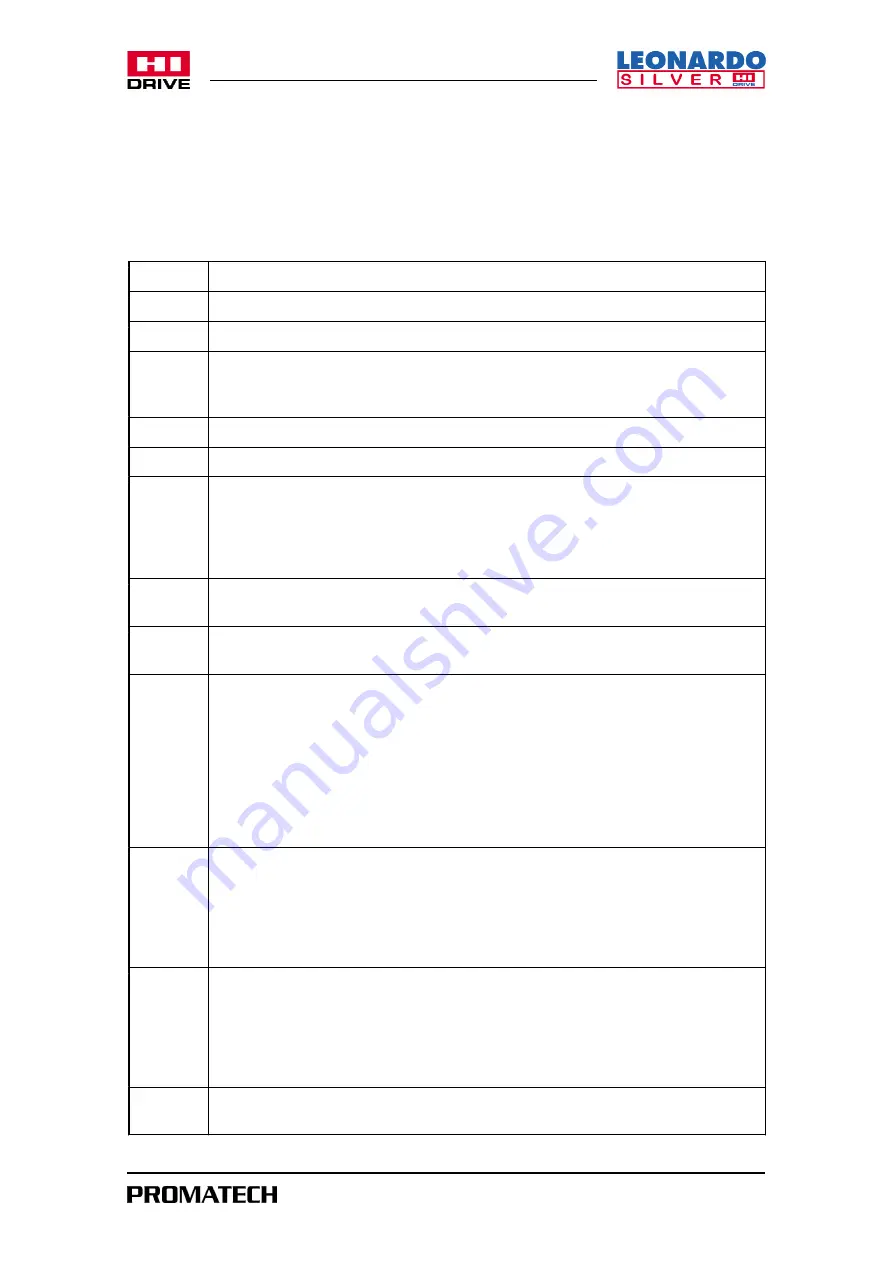

C. HI - Drive alarms

Error codes 13xxx not included in the table below refer to internal software controls. If such an

error occurs, try resetting the alarm by jogging the loom in slow motion; if this fails, switch the loom

off and then back on again. If an error keeps on occurring, contact the Automation department.

Code

Description

13312

No alarms

13313

Timeout on drive start-up: Drive faulty or not connected

13314

Drive fail: Drive faulty or in alarm mode. The drive is switched off when this alarm

occurs. Try switching the loom off and then back on again. Replace the drive if the

error persists.

13315

Incorrect status of the min pressure switch before switching on the oil pump.

13316

13317

Position error: jog the loom in slow motion to reset the alarm. If the alarm persists,

the likely causes are:

- Drive faulty

- motor resolver cable faulty or not connected

- one or more loom/drive interface signals are disconnected or inverted

13318

Tracking error: jog the loom in slow motion to reset the alarm. If the alarm persists,

see the list of likely causes for alarm 13317.

13319

Error in board HDI power supply. Check the board's 24V power supply. Replace

the board if necessary.

13320

Over speed. Depending on the status of the coupling, controls are carried on the

max acceptable speed of the motor. The speed limits are:

- coupling engaged:

from - 500 to 2700 rpm

- with coupling released:

from - 250 to 250 rpm

- during engaging/release:

from -100 to 100 rpm

If the speed of the motor goes beyond these limits, the drive switches itself off and

error 13320 is indicated. You need to switch the loom off and then back on again.

If the error occurs when the loom is stopped, it's likely that there is a problem with

the motor resolver cable.

13321

No encoder coherence before start of tracking. Switch the loom off and then back

on again. If the encoders have not been adjusted: adjust the encoders. This alarm

can happen after adjustment of the encoders or after a software upgrade.

If the alarm persists, the likely causes are:

- main encoder faulty

- drive simulated encoder signals not correct (connections faulty or drive faulty)

13322

No I/O signal coherence during check immediately after switching the drive on.

After switching the drive on, the signals coming from this are always checked. If

there is an anomaly, the drive switches itself off and error 13322 is indicated. Try

switching the loom off and then back on again. If the error persists, check that the

connections between the drive, the loom and the relays are correct; replace the

drive if necessary.

13323

The drive is not disabled on engaging the brake. Reset the alarm by jogging the

loom in slow motion. Replace relay KD2 if this alarm frequently occurs.