Dry Filter Spraybooth Installation and Maintenance Instructions

4

of panel joints. If the Booth canopy is to form part of a dust free environment the panel joints may be sealed with a

proprietary high velocity duct sealant.

8

Exhaust Ducting

Exhaust ducting venting an

Airflow

Spraybooth to atmosphere should be designed and installed by a competent

ventilation engineer. In order to ensure the correct operation of the

Airflow

Spraybooth and also ensure that the correct

volume of air is extracted at its face, the complete ducting system should be sized so as to achieve a maximum pressure

drop of “80Pa”.

Generally speaking, all ductwork should allow air an uninterrupted and smooth passage from the fan unit to the point of

discharge. All bends or transition sections should be designed so as to maintain the cross-sectional area of the fan

discharge diameter and performance checks should be carried out upon completion of the installation. Please Note:

Customers whose solvents consumption requires them to comply with the Environmental Protection Act (E.P.A.) must

pay particular attention to the design criteria of such ductwork as detailed by the Act.

Specialist information and advice can be sought from

Airflow

Product Finishing Limited on the suitability of intended

ductwork systems. Please contact our Sales Department for further advice.

9

Noise

Please refer to the tables over to obtain information of test results obtained from typical

Airflow

Spraybooth

installations. Please Note: Specific individual noise levels should be obtained following installation of your

Spraybooth, as it is impossible for

Airflow

to predict the properties of the acoustic environment in which your

Spraybooth is to be sited.

Please Note:

Airflow

will be pleased to advise on suitable in-duct silencers for use with their range of Spraybooths.

Please contact our Sales Department for further information.

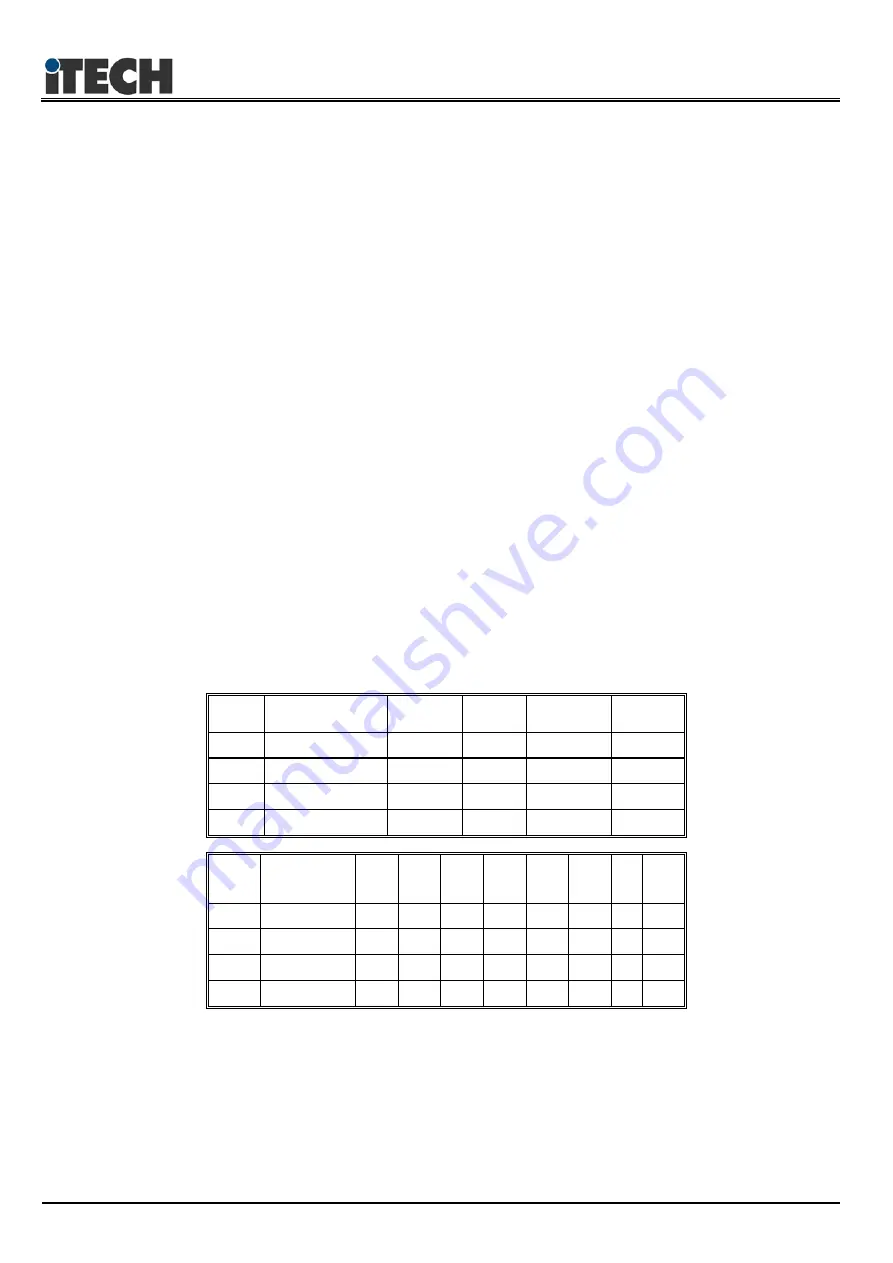

SOUND TABLES

ITEM

IMPELLER CODE

MOTOR

kW

RPM

dB(A) @

3Dia

dBW

A

630/150/10s/30 DEG

1.5

1440

71

91

B

630/150/10s/40 DEG

2.2

1440

73

93

C

630/150/10s/40 DEG

3.0

1620

77

97

D

630/150/10s/40 DEG

4.0

1710

78

98

ITEM

MID

FREQUENCY

Hz

63

125

250

500

1k

2k

4k

8k

A

In-Duct dBW

88

86

85

84

83

78

73

62

B

In-Duct dBW

90

88

87

86

85

80

75

64

C

In-Duct dBW

94

92

91

90

89

84

79

68

D

In-Duct dBW

95

93

92

91

90

85

80

69

10

Electrical Data

Before removing the terminal box cover from the electric motor of the fan unit, ensure that its electrical supply has been

suitably isolated and cannot be switched on.

All electrical connections should be carried our by a qualified and authorised electrician in accordance with local site

regulations and the latest issue of the IEE Regulations.