19

N. Supporter

The supporter furnishes the necessary support to the

inside surface of the stitch so that it does not buckle

as it is being driven into the work material. A lack

of (or insufficient) support will often cause the stitch

crown to wrinkle or the legs of the stitch to buckle.

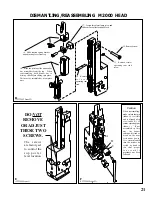

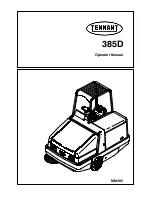

Tighten the supporter spring bushing (Index A, Fig-

ure 18) or replace the spring.

the wire points straight down as in figure 17. Im-

proper straightening of the wire can also cause the

stitch legs to buckle or turn out because they strike

the clincher improperly. Excessive tension on the

wire straightener prevents the grip (Index D) from

feeding the wire smoothly. This causes variation

in leg length.

NOTE:

Check the wire straighteners when changing the

coils to insure the accurate feeding of wire.

If the corners of the top surface of the supporter are

too sharp, or nicked, the corners of the stitch crown

will fracture. If operating properly the supporter

should function as follows:

1. When the bender bar touches the work material

and the legs of the stitch are about to leave

the bender bar grooves the supporter should be

touching the underside of the crown.

2. As the stitch is driven through the work the

supporter is gradually retracted by the driver.

It should remain under the crown of the stitch

until the last instant before the crown touches

the work material.

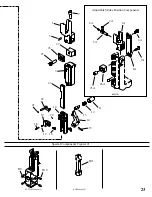

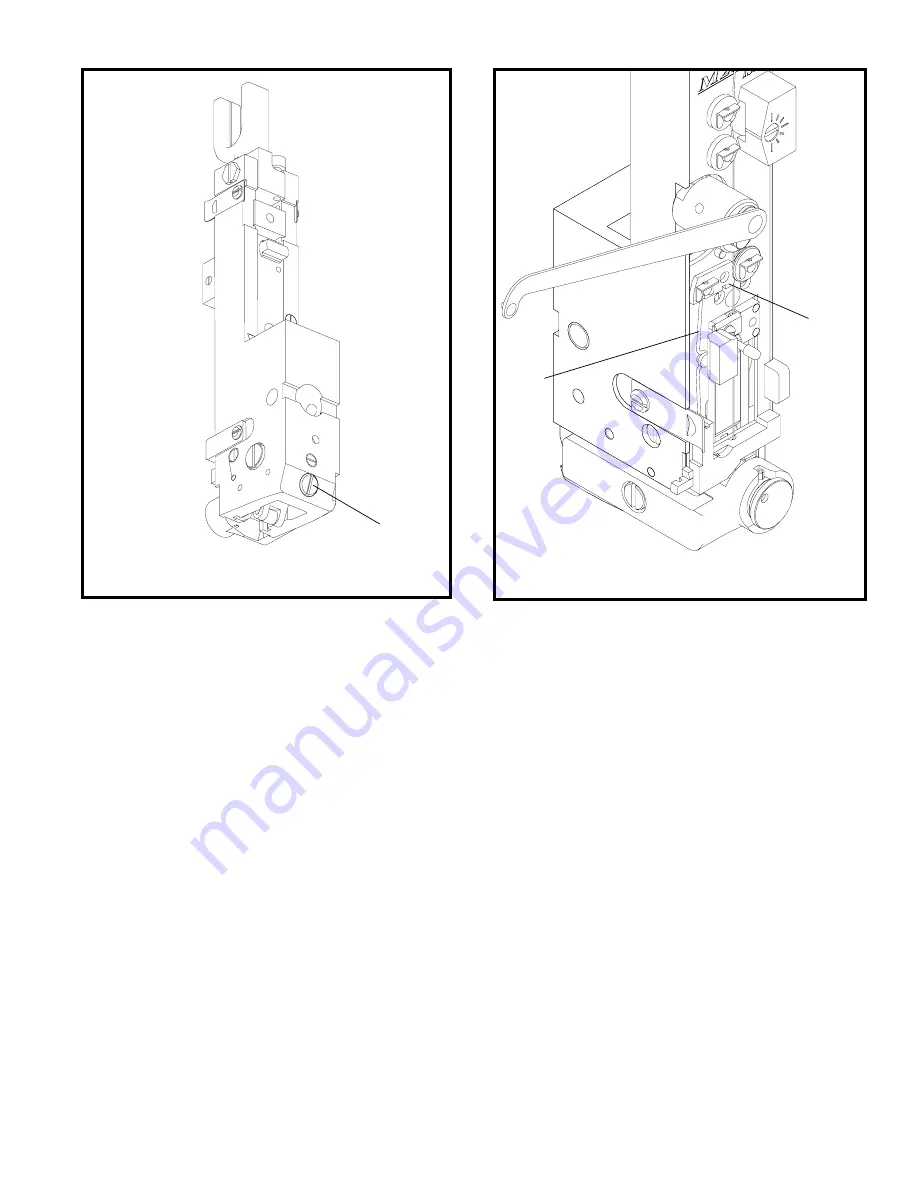

O. Tension Pawl: (Figure 19)

The tension pawl (Index A) and spring (Index B)

apply pressure on the wire to prevent back feed. If

the pawl becomes worn or the spring becomes weak,

the wire feeds backwards resulting in a short wire

draw. Reverse or replace the tension pawl and/or

spring.

A

A

B

Figure 19

(CTTT2605 Scene 18)

Figure 18

(CTTT2605 Scene 11)