12

A. Insufficient or Excessive

Compression

Proper compression of work between the clincher

and the bender bars is necessary so that the stitch

penetrates the work material and clinches correctly.

To test for compression, drive several stitches into

sample work material. With proper compression,

stitches hold the work together firmly and the

clinched legs do not overlap. In the following in-

stances, either one or all of the conditions may

exist: with insufficient compression, stitch legs over-

lap, crown of the stitch is fractured, and the work

mutilated. The method for obtaining proper wire

draw and compression is detailed in the Operation

Section on Page 7 under the heading, "Changing Work

Thickness".

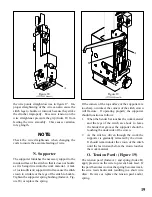

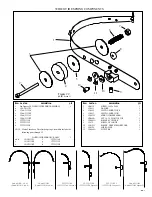

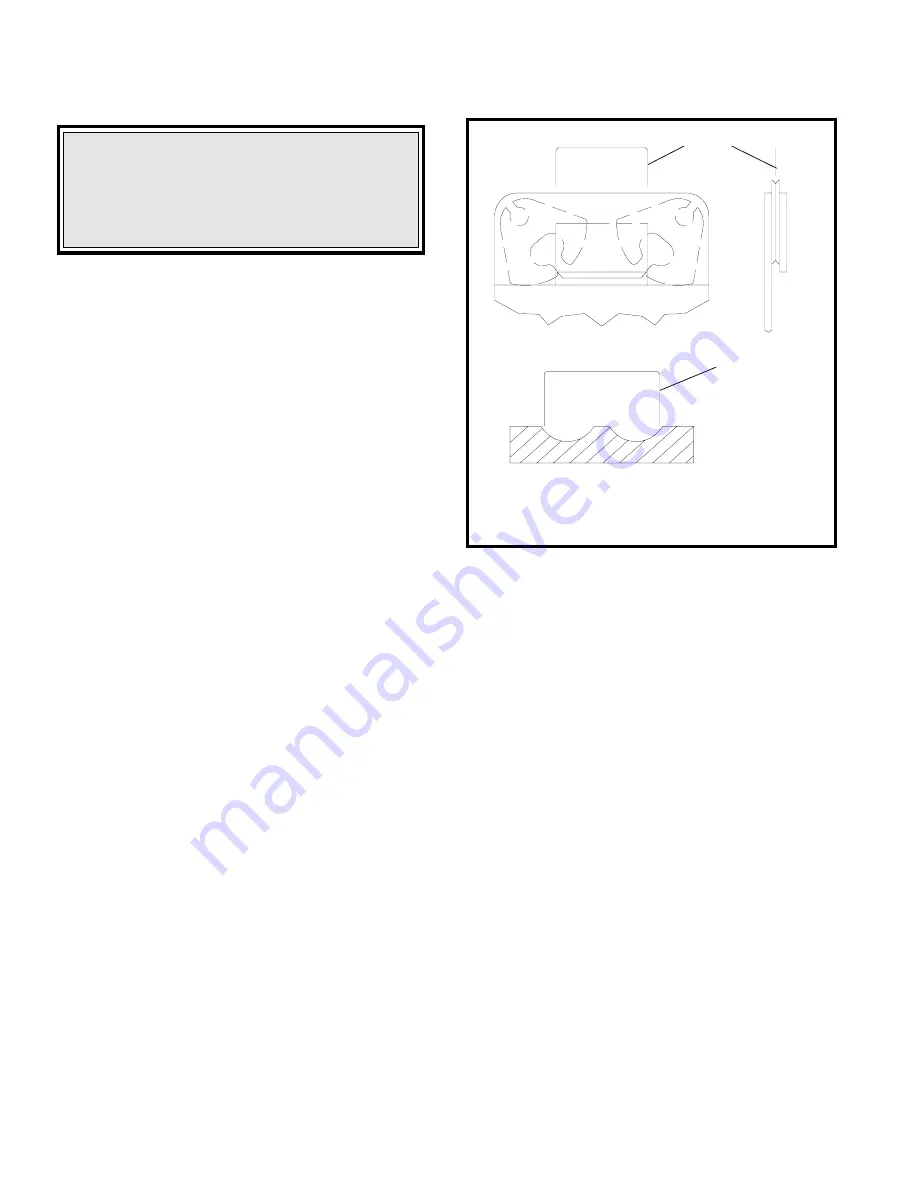

B. Clincher (Figure 8)

The purpose of the clincher is to turn the legs of the

stitch back after they have penetrated the work ma-

terial. There are two types of clinchers:

1. Solid (stationary) Type-makes a loop clinch.

2. Activated (moving) Type-makes a flat clinch.

With the Solid (stationary) Type clincher, the legs

of the stitch must strike the clincher at the same

time and with equal spacing from the outside edges

of the grooves. The grooves in the clincher should

be smooth. Any interference (particularly worn or

pitted grooves), which change the original radii,

will cause the stitch legs to buckle and/or the cor-

ners of the crown to fracture.

With the Activated (moving) Type clincher, the

stitch legs must enter the clincher at the same time

and with equal spacing from each side. When the

CAUTION

Turn Power OFF Before

making Any Adjustments

stitch legs have penetrated the work material, the

moving clinchers are raised to bend the legs to-

wards each other and up flat against the work. The

clincher points must bend both legs of the stitch

against the work with the same force. Clincher

points must always move freely and not bind. Dirt,

wire chips, etc. will cause the points to bind.

The clincher points are in a retracted position in the

clincher box until the stitch legs penetrate the work

material. After the legs penetrate, the clincher points

move upward to give a neat, flat clinch against the

bottom surface of the work material. If the clincher

points remain in the up position, the legs of the

next stitch cannot penetrate the work material, caus-

ing the stitch legs to buckle and/or the corners of

the crown to fracture. Examine the clincher points,

clincher slide for possible binding. Clean and oil.

If clincher points rise to high, they fracture the stitch

legs and/or mar the work. If the points do not rise

high enough, the legs will not clinch flat. Adjust

the height of the clincher points. For most work

the clincher points should rise to be level with the

top of the clincher housing.

ACTIVATED

SOLID

STITCH

STITCH

(SK852F)

Figure 8