13

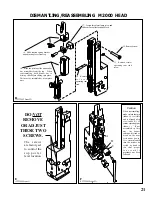

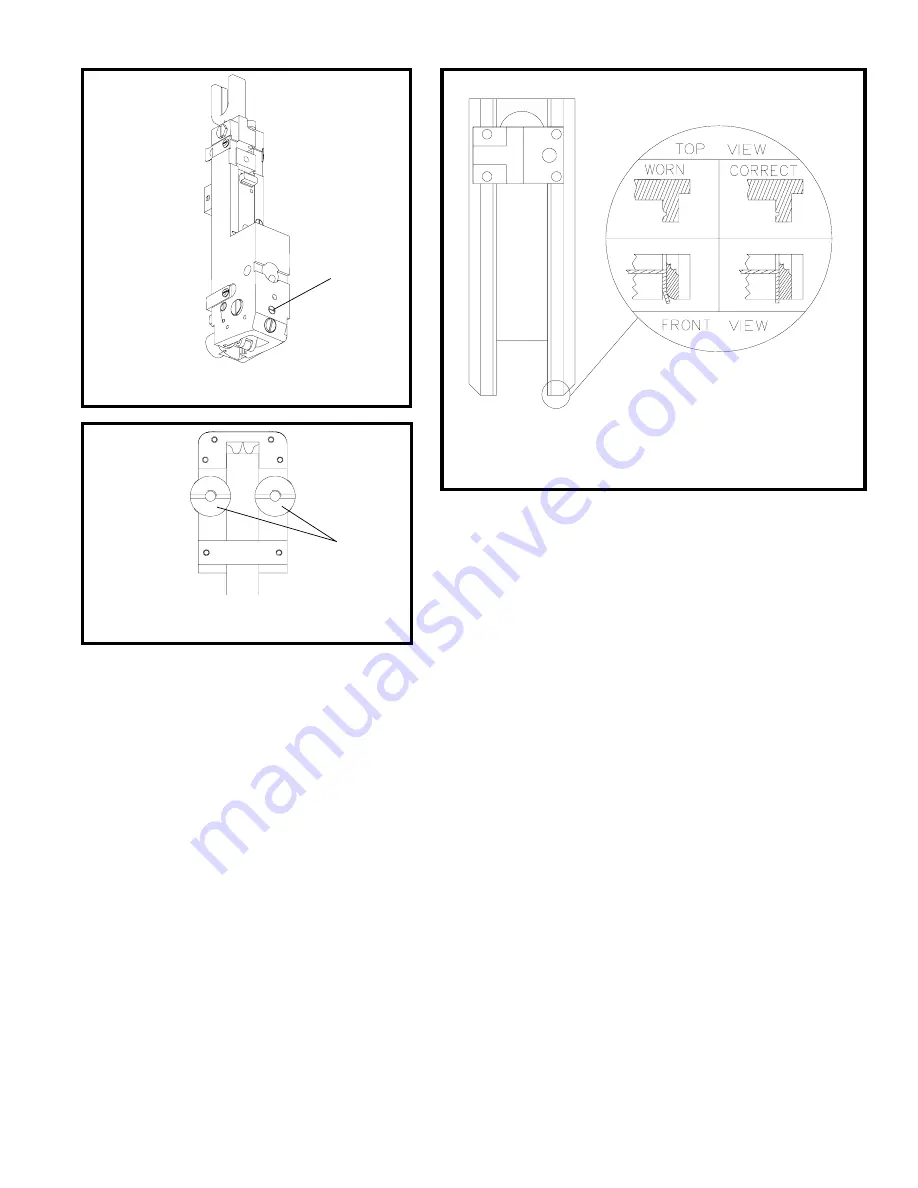

D. Bender Bar (Figure 11)

The bender bar bends the wire over the rotator and

forms it into an unclinched stitch. The legs of the

stitch are guided towards the work material by the

bender bar grooves. The legs of the unclinched

stitch should be perpendicular to the crown. When

the bender bar grooves become worn, the legs tend

to flare out (Figure 11) as they emerge from the

grooves. This causes the legs to strike the clincher

improperly. As a result, one or both legs will

crumple and a broken driver bar or a broken bender

bar can result. If the lower end of the bender bar

grooves become chipped, it will not support the wire

and may cause the stitch to break at the crown. Re-

place the bender bar assembly (See "G" page 15 or

Fig. 12). Other bender bar functions are related to

wire cutting ("I" page 16), and driving ("F" page

14).

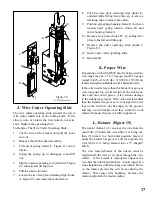

2. To adjust for side-to-side alignment: (Fig. 10)

a. Turn power off. Cycle the stitcher by hand

until legs of the stitch appear just below the

bender bar to determine how far the head or

clincher should be moved to the side.

b. Loosen clincher plate binder nuts (Index A).

c. Move clincher to left or right as required.

d. Tighten binder nuts.

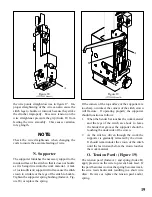

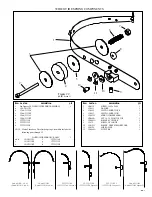

C. Head/Clincher Alignment

(Figure 9, 10)

To test alignment: Drive several stitches into a sec-

tion of material identical to that which is to be

stitched. The clinched legs should be identical and

aligned with each other. If the legs are not in align-

ment make one of the following adjustments:

1. To adjust for front-to-rear alignment: (Fig. 9)

a. Turn power off. Cycle the stitcher by hand

until legs of the stitch appear just below the

bender bar to determine if the head should

be moved to the front or rear.

b. Remove stitcher from machine.

c. Turn the head aligning screw (Index D)

clockwise to move the head backward; coun-

terclockwise to move the head forward.

d. Install stitcher head on machine.

D

A

(SK852I)

Figure 11

(CTTT2605 Scene 11)

Figure 9

(CTTT2605 Scene 12)

Figure 10

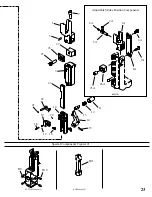

Inject lube into cutter operating slide.