10

Ioline SmarTrac Quick Start Guide

Step 5: Prepare to Cut

Load the Material

Roll

Place a roll of mate-

rial onto the media

rollers. With the

pinchwheels up,

thread the material

through the machine.

Position the Pinchwheels Over the Drive Shaft

Move the material and

pinchwheels from side to side to find a position

where the outermost drive wheels are on the material about 1 inch from

each edge, and over a drive shaft segment. Use the drive shaft markers

(

Figure 16

) to determine where to place the wheels. The long drive shaft

segment on the right

side of the machine

allows many pinch-

wheel positions for

a variety of material

widths. Evenly space

the inner idler wheel(s)

(I/S 85, 110 and 130 &

SC-40 and -48 mod-

els) over drive shaft

segments. Make sure

there is a minimum of

one inch between the

edge of the roll and the

stand leg.

Square the Material

Lift the pinchwheels off the drive shaft using the pinchwheel lever.

Pull enough material through the machine so that it reaches the roll.

Align the edge of

the material with

the edge of the roll,

making sure the

material is flat and

square in the ma-

chine. Ensure that the

outer pinchwheels

are at least one inch

from the edge of the

material. Lower the

pinchwheels.

Figure 17.

Align the material.

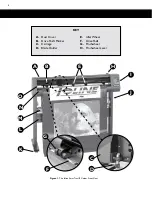

Figure 15.

Material loaded on media roller.

Figure 16.

Place pinchwheels under drive shaft markers.

Drive Shaft

Marker

Drive Shaft

Segment