11

Quick Setup

Position the Material

Do not let the material become suddenly tight between the cutter

and the material roll. Manually unroll a few feet of material from

the roll to create a

slack loop behind

the machine. Use

the

Arrow

keys on

the keypad to move

material through the

cutter to check align-

ment. Adjust the ma-

terial if necessary so

that it feeds straight.

Position the material

edge two inches in

front of the blade;

Place the carriage an

inch from the right

edge.

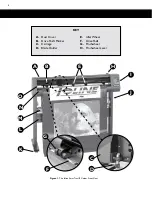

Figure 18.

Leave slack in the material.

Insert a Blade,

Load the Holder

in the Jaw

Unscrew the foot

from the blade

holder. Insert a blade

into the hole in the

blade holder, mak-

ing sure it is fully

seated. Replace the

foot and adjust it so

that the blade tip is

barely inside the foot

with no blade exposed. Loosen the thumb screw on the carriage jaw

and insert the blade holder. The

flange slides into the slot in the

jaw.

Rotate the clamp down onto the

flange and tighten the thumb screw

until the blade holder is held securely in place.

Adjust the Blade

Exposure and

Force

Turn the

Force

knob

on the keypad clock-

wise to maximum.

Press the

Test Cut

key. There should be

little or no scoring of

the material. Turn the

foot 1/8-turn clock-

wise (from the bottom). Press the

Test Cut

key. Weed the test cut

pattern and examine cut quality. Continue adding blade exposure

Figure 20.

Adjusting the blade exposure.

Figure 19.

Inserting the blade (left) and the blade

holder (right).

Deeper

Cut

Blade

Blade

Holder

Foot

Flange

Be very careful when handling

the blades as they are sharp and

brittle and the tips can chip or

break. Using a hard surface to

insert the blade may damage it.

Note

i