5 USAGE

Part No 1143155

47

Invacare® Formula™ CG Seating

FIGURE

9

LCD Display Screens - Main Screen

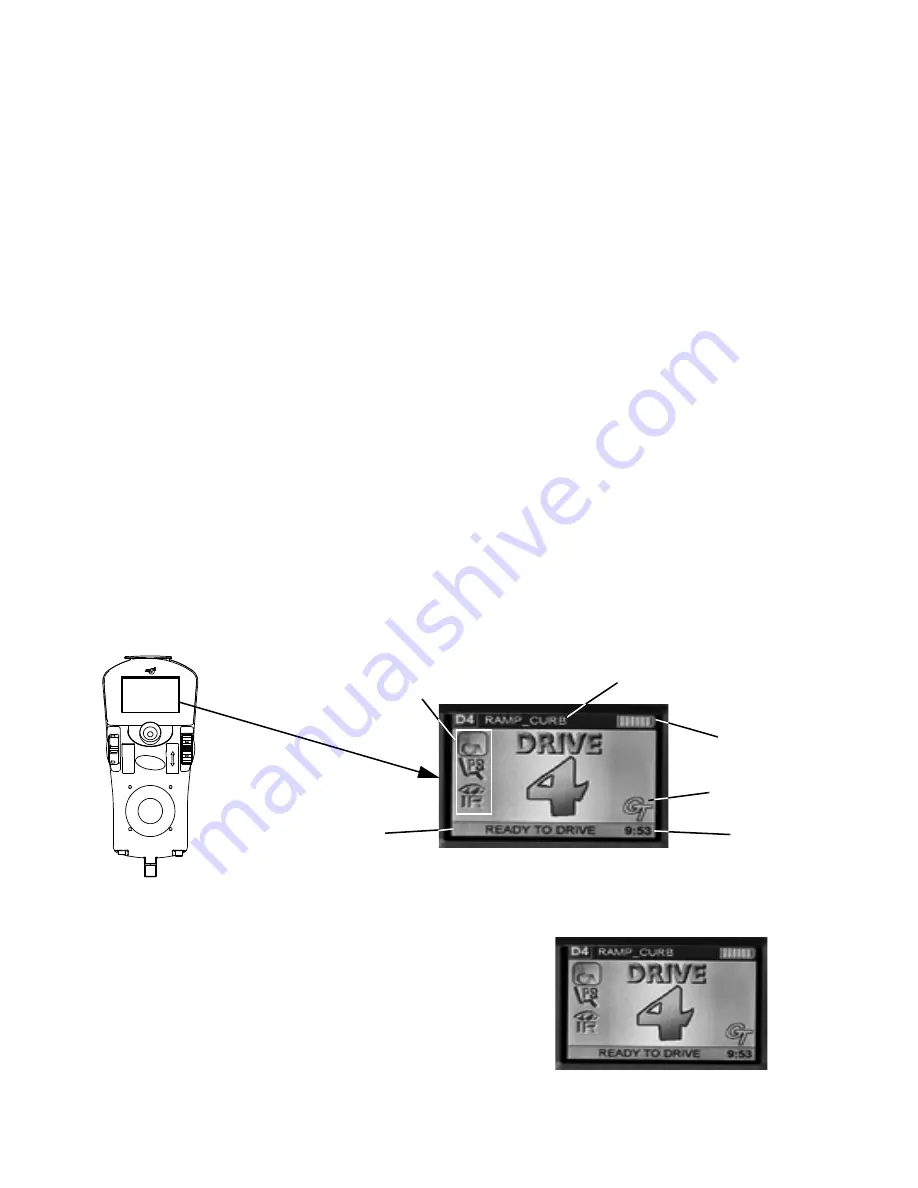

Driving Screen

This screen is shown when the operator issues a drive command and the

Drive Icon on the main screen was highlighted.

FIGURE

10

LCD Display Screens - Driving Screen

Available Modes in this Drive

(Must be Programmed. Top, Highlighted Icon

Indicates Selected Mode)

Clock

Battery Gauge

Display

Status/Info Message Area

Status Indicator

Drive Profile Name

For this procedure, refer to FIGURE

10.

The Drive’s name, warning/info message, status

icon and battery indicator are displayed on this

screen.