22

R05

S

ET

-U

P

P

ROCEDURES

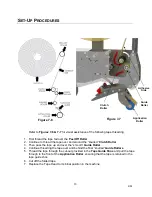

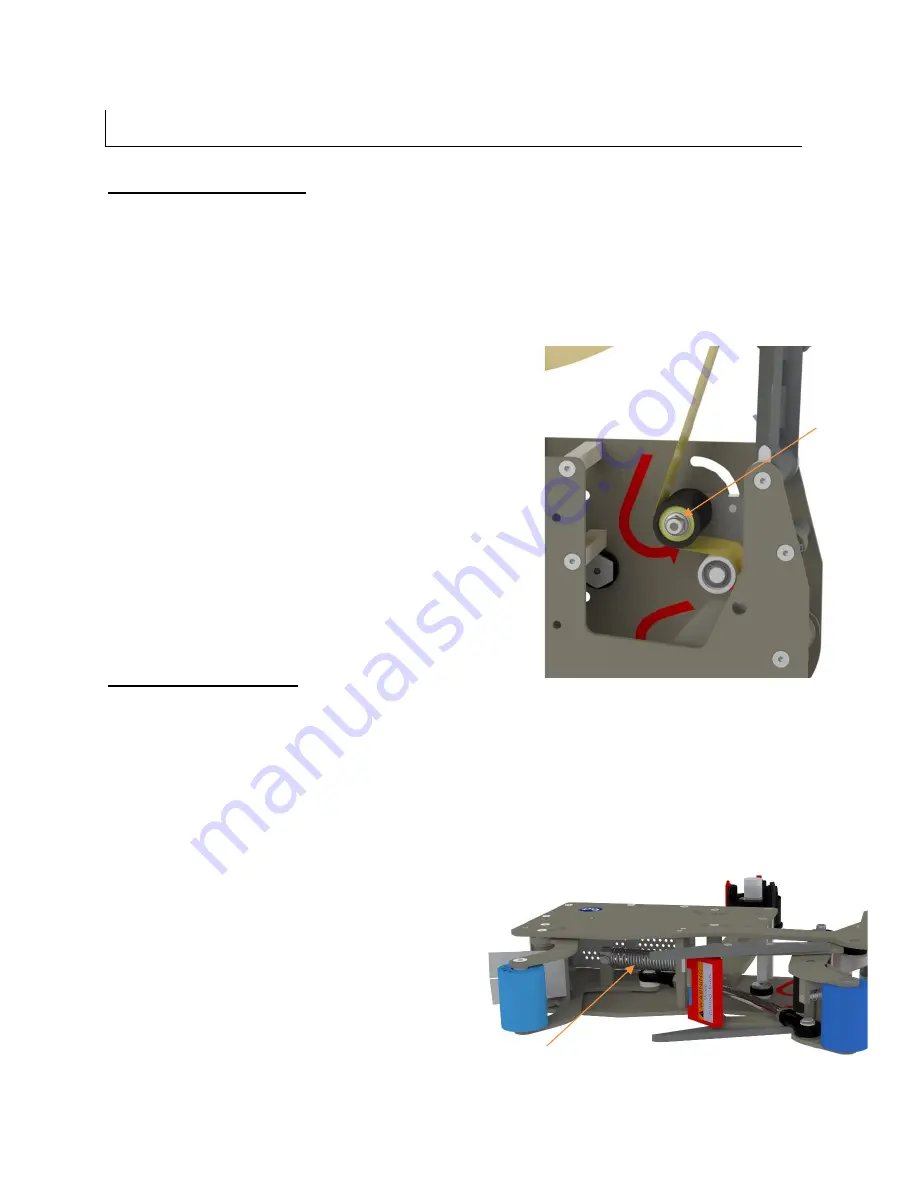

Clutch Roller Adjustment

The one-way clutch roller assures that the tape does not go backwards any time during

dispensing, further more it is a tool in achieving correct front tape leg length.

Different quality tapes have different adhesives and release coats. This has an effect on the

dispensing, e.g. very “sticky” tapes are peeling-off with higher resistance, so they will need

minimal tension on the clutch roller. Tapes that unwind easily may need more tension on the

clutch roller to achieve uniform front tape leg length during sealing.

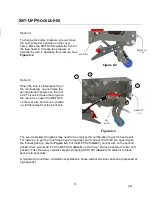

Main Spring Adjustment

1.) To decrease the clutch roller’s tension, turn the

M6 friction nut at the end of roller

counterclockwise, it requires a 10 mm wrench. Do

not loosen to the point that the roller could be

moved laterally on the shaft.

2.) To increase the clutch roller’s tension one needs

to turn the M6 friction nut clockwise. Make tiny

increments (less than eighths of a turn) at a time

and check the sealing results before going any

further. Once the disc spring has been over

squeezed it may lose its properties. To avoid this

eventuality, pay attention.

The main spring retainers are set at the factory for the most common applications. The top tape head

will need lighter springs, UPH0910 or UPH0911, while the bottom positioned tape head will need

heavier springs, UPH1091.

The ET-X 3-inch tape heads can run up to 140 ft/min line speed, the 2-inch version up to 150 ft/min

line speed. In applications one might have normal cases, over filled cases, void filled cases, flimsy

corrugated boxes, stiff double fluted cases. The speed and the nature of the box will determine the

best main spring setting. Typically, the higher the line speed the more tension one requires from the

main spring. To increase the rollers’ pressure we have the following techniques to choose from in

order of ease:

Option 1:

If one needs a little bit more (~15%) pressure

on the application rollers and have a stainless

steel spring mounted on the tape head, may

change the spring for the music wire version.

(UPH0911 for top tape head and UPH1091 for

bottom tape head)

MAIN SPRING

Figure 8-1

M6

FRICTION

NUT

Summary of Contents for ET xtreme Series

Page 1: ...1 R05 ET xtreme STANDARD TAPE HEAD Serial Numbers UH230T UH430T ...

Page 2: ...2 R05 ...

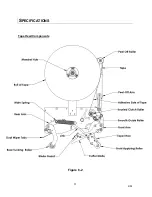

Page 10: ...10 R05 SPECIFICATIONS UUUTape Head Dimensions Figure 6 1 ...

Page 11: ...11 R05 SPECIFICATIONS UUU Tape Head Components Figure 6 2 ...

Page 43: ...43 R05 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 44: ...4 6 10 8 1 9 3 5 7 2 11 12 13 44 ...

Page 46: ...1 15 2 3 6 10 12 14 7 11 8 9 5 4 16 14 13 13 4 18 17 46 ...

Page 48: ...6 11 8 14 2 12 9 7 10 5 3 3 13 48 ...

Page 50: ...6 7 15 11 10 14 4 2 9 3 5 13 12 8 1 16 50 ...

Page 52: ... 8 8 ...

Page 53: ... 7 0 3 57 6 5 37 21 8 47 8 47 83 8 52 5 83 2035 66 21 635 1 83 8 52 5 ...

Page 54: ...2 4 1 5 3 54 ...

Page 56: ... 8 8 ...

Page 58: ... 86 86 ...

Page 60: ...2 4 1 3 5 6 5 60 ...

Page 62: ...2 3 6 5 1 8 4 12 9 7 9 10 11 62 ...

Page 64: ...5 15 7 6 12 2 14 4 3 13 10 8 9 1 11 16 64 ...

Page 66: ...3 1 2 2 1 3 Standard Tape Head Mirror Tape Head 66 ...

Page 68: ...5 2 10 4 11 3 8 6 7 1 9 12 68 ...

Page 70: ...1 3 2 70 ...

Page 72: ... 8 8 ...

Page 74: ...6 1 2 5 3 4 74 ...

Page 76: ...19 4 9 16 6 7 5 8 1 11 3 10 14 12 15 13 18 17 2 20 76 ...

Page 78: ...1 2 No Tape options are available 78 ...