441 01 2613 05

29

Specifications are subject to change without notice

MANIFOLD PRESSURE AND ORIFICE SIZE FOR HIGH ALTITUDE APPLICATIONS

Table 6

NATURAL GAS MANIFOLD PRESSURE (in wc)

HEATING

VALUE

at ALTITUDE

BTU/CU. FT.

MEAN ELEVATION ABOVE SEA LEVEL

!

ft(m)

0 to 2000

(0 to 610)

2001 to 3000

*

(610 to 914)

*

3001 to 4000

(915 to 1219)

4001 to 5000

(1220 to 1524)

5001 to 6000

(1524 to 1829)

6001 to 7000

(1829 to 2134

)

7001 to 8000

(2134 to 2438)

Orifice

No.

Manifold

Pressure

Orifice

No.

Manifold

Pressure

Orifice

No.

Manifold

Pressure

Orifice

No.

Manifold

Pressure

Orifice

No.

Manifold

Pressure

Orifice

No.

Manifold

Pressure

Orifice

No.

Manifold

Pressure

700

!!

!!

!!

!!

!!

!!

!!

!!

!!

!!

!!

!!

41

3.7

725

!!

!!

!!

!!

!!

!!

!!

!!

!!

!!

41

3.7

41

3.4

750

!!

!!

!!

!!

!!

!!

!!

!!

!!

!!

41

3.5

42

3.6

775

!!

!!

!!

!!

!!

!!

!!

!!

41

3.6

42

3.6

42

3.3

800

!!

!!

!!

!!

!!

!!

41

3.6

42

3.7

42

3.4

42

3.1

825

!!

!!

!!

!!

41

3.7

41

3.4

42

3.5

42

3.2

42

2.9

850

!!

!!

!!

!!

41

3.5

42

3.6

42

3.3

42

3.0

42

2.8

875

!!

!!

41

3.6

42

3.6

42

3.4

42

3.1

42

2.8

42

2.6

900

!!

!!

42

3.7

42

3.4

42

3.2

42

2.9

42

2.7

42

2.5

925

41

3.7

42

3.5

42

3.3

42

3.0

42

2.8

42

2.5

44

3.3

950

41

3.5

42

3.3

42

3.1

42

2.9

42

2.6

42

2.4

44

3.1

975

42

3.7

42

3.2

42

2.9

42

2.7

42

2.5

44

3.2

45

3.6

1000

42

3.5

42

3.0

42

2.8

42

2.6

42

2.4

45

3.7

45

3.4

1050

42

3.2

42

2.7

42

2.5

44

3.3

45

3.6

!!

!!

!!

!!

1100

43

3.6

42

2.5

44

3.2

45

3.6

!!

!!

!!

!!

!!

!!

Conversion: 1 in wc = .25 kPa

NOTE:

Natural gas data is based on 0.60 specific gravity. For fuels with different specific gravity consult the National Fuel Gas Code ANSI Z223.1/NFPA

54

!

2009 or National Standard of Canada, Natural Gas And Propane Installation Code CSA B149.1

!

05.

*

In the USA,

derating of these furnaces at 2% (Natural Gas) and 4% (Propane Gas) has been tested and design

!

certified by CSA.

In Canada

, the input rating must be derated 5% (Natural Gas) and 10% (Propane Gas) for altitudes of 2,000 to 4,500 (610 to

1372m) above sea level. Use the 2001 to 3000 (610 to 914m) column in

Table 6

and

Table 7

.

Table 7

PROPANE GAS MANIFOLD PRESSURE (in wc)

HEATING VALUE

at ALTITUDE

BTU/CU. FT.

MEAN ELEVATION ABOVE SEA LEVEL

!

ft(m)

0 to 2000

(0 to 610)

2001 to 3000

*

(610 to 914)

*

3001 to 4000

(915 to 1219)

4001 to 5000

(1220 to 1524)

5001 to 6000

(1524 to 1829)

6001 to 7000

(1829 to 2134)

7001 to 8000

(2134 to 2438)

2500

10.0

10.0

9.0

10.0

9.4

8.5

10.0

Orifice Size

#54

#54

#54

#55

#55

#55

#56

Conversion: 1 in wc = .25 kPa

NOTE:

Propane data is based on 1.53 specific gravity. For fuels with different specific gravity consult the National Fuel Gas Code ANSI Z223.1/NFPA

54

!

2009 or National Standard Of Canada, Natural Gas And Propane Installation Code CSA B149.1

!

05.

*

In the USA,

derating of these furnaces at 2% (Natural Gas) and 4% (Propane Gas) has been tested and design

!

certified by CSA.

In Canada

, the input rating must be derated 5% (Natural Gas) and 10% (Propane Gas) for altitudes of 2,000 to 4,500 (610 to

1372m) above sea level. Use the 2001 to 3000 (610 to 914m) column in

Table 6

and

Table 7

.

The burner orifice part nos. are as follows:

Orifice #41

1096942

Orifice #42

1011351

Orifice #43

1011377

Orifice #44

1011352

Orifice #45

1011353

Orifice #54

1011376

Orifice #55

1011354

Orifice #56

1011355

High Altitude Air Pressure Switch

The factory

!

installed pressure switch need NOT be changed for

any furnace installations from sea level up to and including 8,000

′

(2438m) altitude

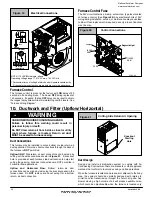

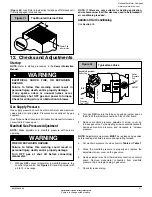

Changing Orifices

1. After disconnecting power and gas supply to the furnace,

remove the burner compartment door, exposing the burner

compartment.

2. Disconnect gas line from gas valve so manifold can be

removed.

3. Disconnect wiring at gas valve. Be sure to note the proper

location of all electrical wiring before being disconnected.

4. Remove the four (4) screws holding the manifold and gas

valve to the manifold supports. Do not discard any screws.

See

Figure 33.

5. Carefully remove the manifold assembly.

6. Remove the orifices from the manifold and replace them with

proper sized orifices. See

Figure 34.

7. Tighten orifices so they are seated and gas

!

tight. See

Figure 34.

8. Reassemble all parts in reverse order as removed. Be sure to

engage the main burner orifices in the proper openings in the

burners.

National Excelsior Company

www.excelsiorhvac.com

Subject to change without notice.