18

441 01 2613 05

Specifications are subject to change without notice

Vent dampers on any appliance connected to the common vent

can cause condensation and corrosion in the venting system. Do

not use vent dampers on appliances common vented with this

furnace.

8. Gas Supply and Piping

CARBON MONOXIDE POISONING, FIRE AND

EXPLOSION HAZARD

Failure to follow this warning could result in

personal injury, death, and/or property damage.

Models designated for Natural Gas are to be used

with Natural Gas ONLY, unless properly converted to

use with Propane gas.

!

WARNING

Gas Supply Requirements

•

Use only the type of gas approved for this furnace. See rating

plate for approved gas type.

•

Gas input must not exceed the rated input shown on the rating

plate. Overfiring will result in failure of heat exchanger and

cause dangerous operation.

•

Do not allow minimum supply pressure to vary downward.

Doing so will decrease input to furnace. Refer to

Table 3

for

gas supply. Refer to

Table 6

and

Table 7

for manifold

pressures.

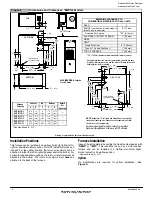

Table 3

Gas Pressures

Gas Type

Supply Pressure

Recommended

Max.

Min.

Natural

7 in wc

(1744 Pa)

14 in wc

(3487 Pa)

4.5 in wc

1121 Pa)

Propane

11 in wc

(2740 Pa)

14 in wc

(3487 Pa)

11 in wc

(2740 Pa)

Gas Piping Requirements

NOTE:

The gas supply line must be installed by a qualified service

technician in accordance with all building codes.

NOTE:

In the state of Massachusetts.

a. Gas supply connections MUST be performed by a

licensed plumber or gas fitter.

b. When flexible connectors are used, the maximum length

shall not exceed 36

″

(914.4mm).

c.

When lever handle type manual equipment shutoff

valves are used, they shall be T

!

handle valves.

d. The use of copper tubing for gas piping is NOT approved.

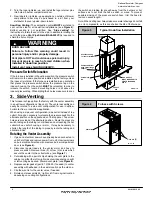

1. Install gas piping in accordance with local codes, or in the

absence of local codes, the applicable national codes.

2. It is recommended that a manual equipment shutoff valve be

installed in the gas supply line outside the furnace. Locate

valve as close to the furnace as possible where it is readily

accessible. Refer to

Figure 12.

FIRE HAZARD

Failure to follow this warning could result in

personal injury or death.

Use wrench to hold furnace gas valve when turning

elbows and gas line to prevent damage to the gas

valve and furnace.

!

WARNING

ON

OFF

ON

OFF

Use elbows and 3

#

(76.2mm) pipe nipple to con

nect valve to piping when using right side gas

pipe entry.

* Union may be installed inside the cabinet when necessary because of clearances.

Drip Leg and Union, Union* should be outside the

cabinet. Manual shut-off valve MUST be upstream of

dripleg, union, and furnace.

Propane Low

pressure

switch.

25

!

24

!

86

3

#

(76.2mm)

pipe nipple

Manual shut-off

valve

Typical Gas Piping (N8MP)

Figure 12

Representative drawing only, some models may vary in appearance.

National Excelsior Company

www.excelsiorhvac.com

Subject to change without notice.