24

441 01 2613 05

Specifications are subject to change without notice

low

!

velocity filters meet the minimum size areas for 300 FPM or

less.

Figure 22

Optional Duct Standoff

!

NAHA001TK

in(mm)

Filter

20 x 25 (508 x 635 mm)

Optional Filter Rack

16

(406)

14.5

(368)

25

1/16

(637)

25

1/16

(637)

6

7/8

(175)

23

1/2

(570)

18

1/2

(470)

22

1/2

(572)

20

(508)

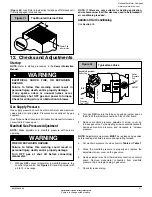

Optional Filter Rack Installation: Side Return

Center the filter rack on the side panel, flush with the bottom edge

of the furnace. Mark the fastening holes. Drill the fastening holes

in the side panel and fasten the filter rack in place with sheet metal

screws. See

Figure 23

and

Figure 24

.

Figure 23

Side Return Filter Rack

Filter

25-23-05-4a

25-23-05-3

Filter

Filter

Using Two

Filter Racks

Figure 24

Filters Installed on Two Sides

Internal Filter in Bottom-Return Installation

When installing a bottom

!

mounted filter inside the furnace, install

the filter clips on the edge of the bottom duct opening with the wider

end of the clips toward the blower, as shown in

Figure 25.

Clips

may be obtained from your distributor or fabricated from sheet

metal (

Figure 26

). Insert filter into side clips first and push filter

back until it is fully engaged into back clip.

Center Clip

side-to-side

Figure 25

Bottom Mounted Filter

25-24-18-1

9

″

Figure 26

Filter Clip Construction

!

in(mm)

26 Ga. Galvanized Steel

FAST part number 1008482

3

″

1

1

/

4

″

1

1

/

2

″

11

/

16

″

(76.2)

(38.1)

(31.8)

(27)

NOTE:

If filters are only suitable for heating application, advise

homeowner that filter size may need to be increased if air

conditioning is added.

Addition Of Air Conditioning

When a refrigeration coil is used in conjunction with this furnace, it

must be installed on the discharge side of the furnace to avoid

condensation in the heat exchanger. All furnaces are designed

with a break

!

away duct flange on the supply air side of the furnace.

This allows for installation in the horizontal right or downflow

applications. The coil installation instructions must be consulted

for proper coil location and installation procedures. With a parallel

flow arrangement, dampers must be installed to prevent chilled air

from entering the furnace. If manually operated dampers are

used, they must be equipped with a means to prevent operation of

either unit unless the damper is in full heat or full cool position.

Copper or plastic tubing may be used for the condensate drain line.

National Excelsior Company

www.excelsiorhvac.com

Subject to change without notice.