Intermec ColorCoder V4 – Service Manual Ed. 1

51

Chapter 2 Operation and Timing

2.3 Ink Supply System, cont'd.

2.3:A Outline, cont'd.

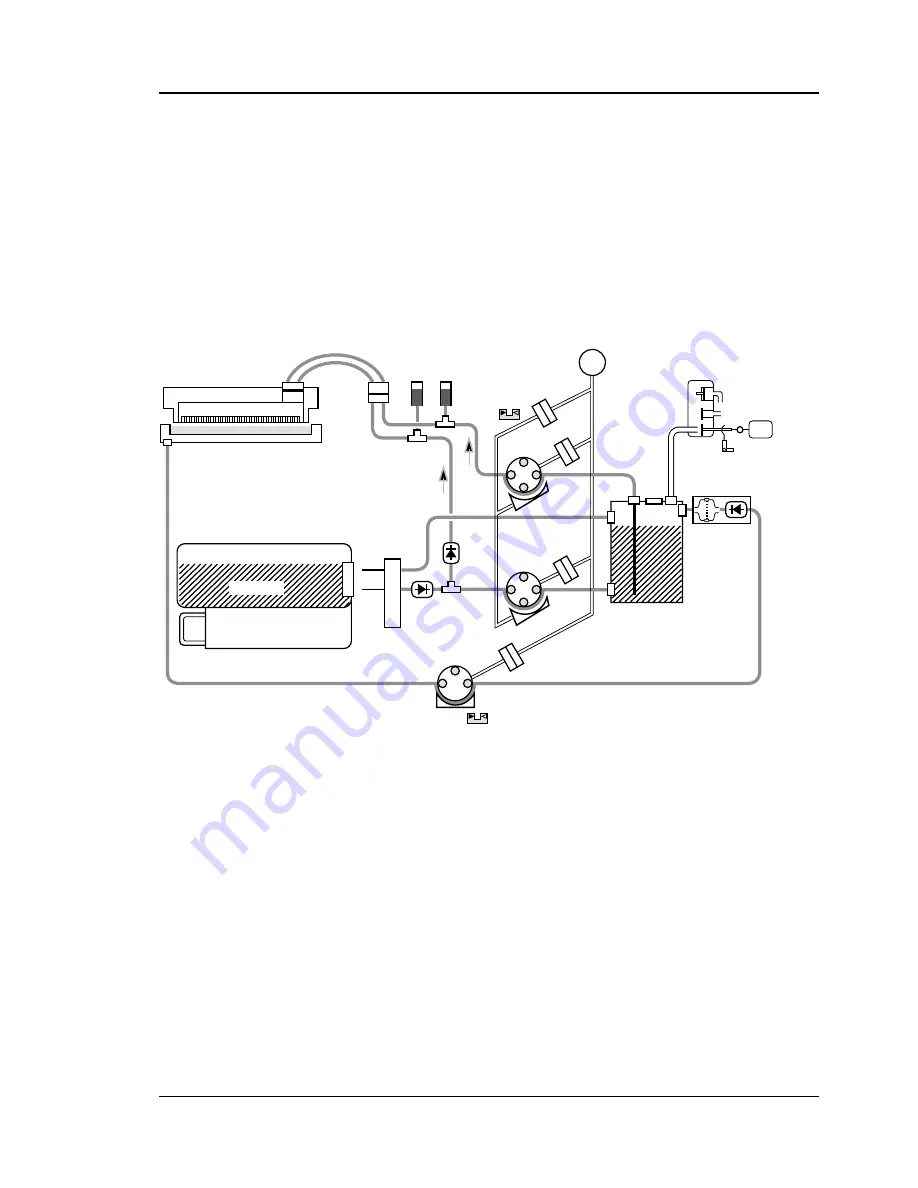

Figure 2-35

Outline of Operation, cont'd.

Operation of Printing Mode

During printing, the open/close latch of the sub-tank is opened and

the pressure/release cam is released, so that the suction pump and

pressure pump are stopped and released. When the pressure of the

ink inside the BJ head and the tubing slightly goes down because of

ink ejection, the ink is replenished to the BJ head from the sub-tank

by means of a capillary tube phenomenon of the BJ head nozzles.

Error Detection

In the ink supply system. the following types of errors are detected.

• No ink cartridge error: The presence or absence of the ink car-

tridge is checked for the ink room.

“CHECK CART.” takes place, when no

ink-cartridge in the ink room.

• Empty ink error :

The amount of the ink remained is checked

for the sub-tank. The error is detected at

the time when the ink supply operation is

completed. “Empty ink error” takes place

when the ink-remaining-quantity-detec-

tion sensor attached to the sub-tank does

sense no ink at the time when the ink

supply operation is completed.

• Ink overflow error:

“26 SERVICEMAN CALL” takes place,

when the ink leaks inside the printer and

reaches the ink leak sensor.

Recovery pump

home position

sensor

Recovery pump

SL

Outlet

Release value

Breather

unit

Inlet

Latch

solenoid

(Pull)

Latch lever

(Down)

Sub tank

One way

clutch

Pressure

pump

Air buffer

M

Pump motor

Pressure cam

home position

sensor

Cam

pressure

release

clutch

Pump

retainer

Suction

clutch

Pressure

clutch

Pump retainer

Filter unit

BJ Head

Restoration tub unit

Tube

station

Needle block

Ink cartridge

Suction

pump

Ink tank