Ver0.1

Page

13

of

53

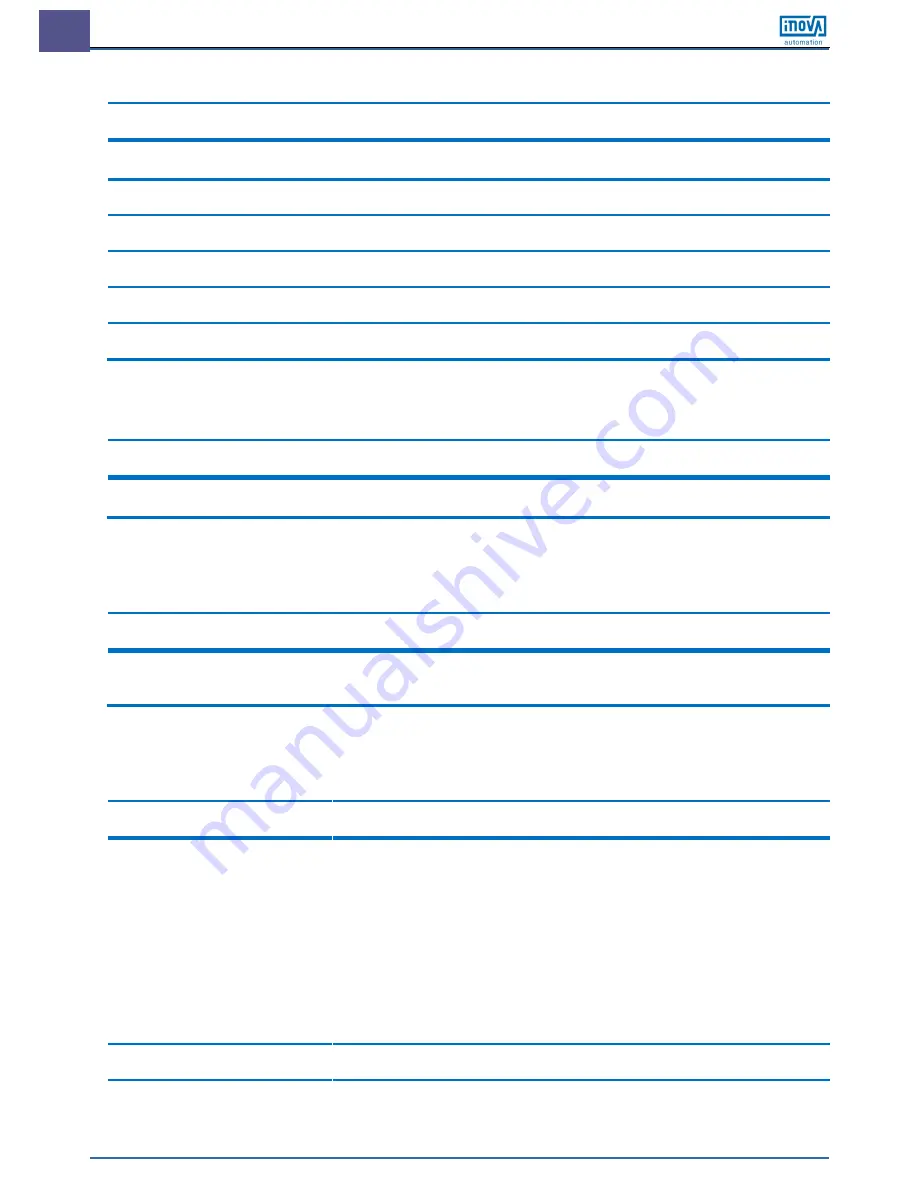

Step 2: Set Motor Parameters

Function

code

Parameter Name

Setting Range

Unit

Default

Commission

F1-00

Motor type

0: Common asynchronous motor

1: Variable-frequency asynchronous motor

N.A

0

F1-01

Rated motor power

0.1 to 30.0

kW

Model

dependent

F1-02

Rated motor voltage

1 to 1000

V

Model

dependent

F1-03

Rated motor current

0.01 to 655.35

A

Model

dependent

F1-04

Rated motor frequency 0.01 to maximum frequency

Hz

Model

dependent

F1-05

Rated motor rotational

speed

1 to 65535

RPM

Model

dependent

Step 3: Set Motor Controlling Mode

Function

code

Parameter Name

Setting Range

Unit

Default

Commission

F0-01

Motor 1 control mode

0: Sensorless vector control (SVC)

2: Voltage/Frequency control (V/F)

N.A

2

Step 4: Perform Motor Tuning If It’s SVC Control Mode

Function

code

Parameter Name

Setting Range

Unit

Default

Commission

F1-37

Auto-tuning selection

0: No auto-tuning

1: Static auto-tuning

2: Complete dynamic auto-tuning

N.A

0

Step 5: Set Frequency Reference

Function

code

Parameter Name

Setting Range

Unit

Default

Commission

F0-03

Main frequency source

X selection

0: Digital setting F0-08

(non-retentive at power failure)

1: Digital setting F0-08

(retentive at power failure)

2: AI1

3: Reserved

4: Reserved

5: Pulse setting (DI5)

6: Multi-reference

7: Simple PLC

8: PID

9: Communication setting

N.A

0

F0-04

Auxiliary frequency

source Y selection

The same as F0-03 (Main frequency source X

selection)

N.A

0