7

INSTALLATION

Prior to installing the hoist, carefully inspect it for possible

shipping damage.

Hoists are supplied fully lubricated from the factory.

Lubrication of the load chain is recommended before initial

hoist operation.

CAUTION

• Owners and users are advised to examine specific, local or

other regulations, including American National Standards

and/or OSHA Regulations which may apply to a particular

type of use of this product before installing or putting hoist

to use.

WARNING

• A falling load can cause injury or death. Before installing,

read "Safety Information."

Mounting

Make certain your hoist is properly installed. A little extra time

and effort in doing so can contribute a lot toward preventing

accidents and helping you get the best service possible.

Always make certain the supporting member from which the

hoist is suspended or attached is strong enough to support the

weight of the hoist plus the weight of the maximum rated load

plus a generous factor of at least 500% of the combined weights.

If the hoist is suspended by a top hook, the supporting member

should rest completely within the saddle of the hook and be

centered directly above the hook shank. Do not use a supporting

member that tilts the hoist.

Hook Mounted Hoist Installation

Place hook over mounting structure. Make sure hook latch is

engaged.

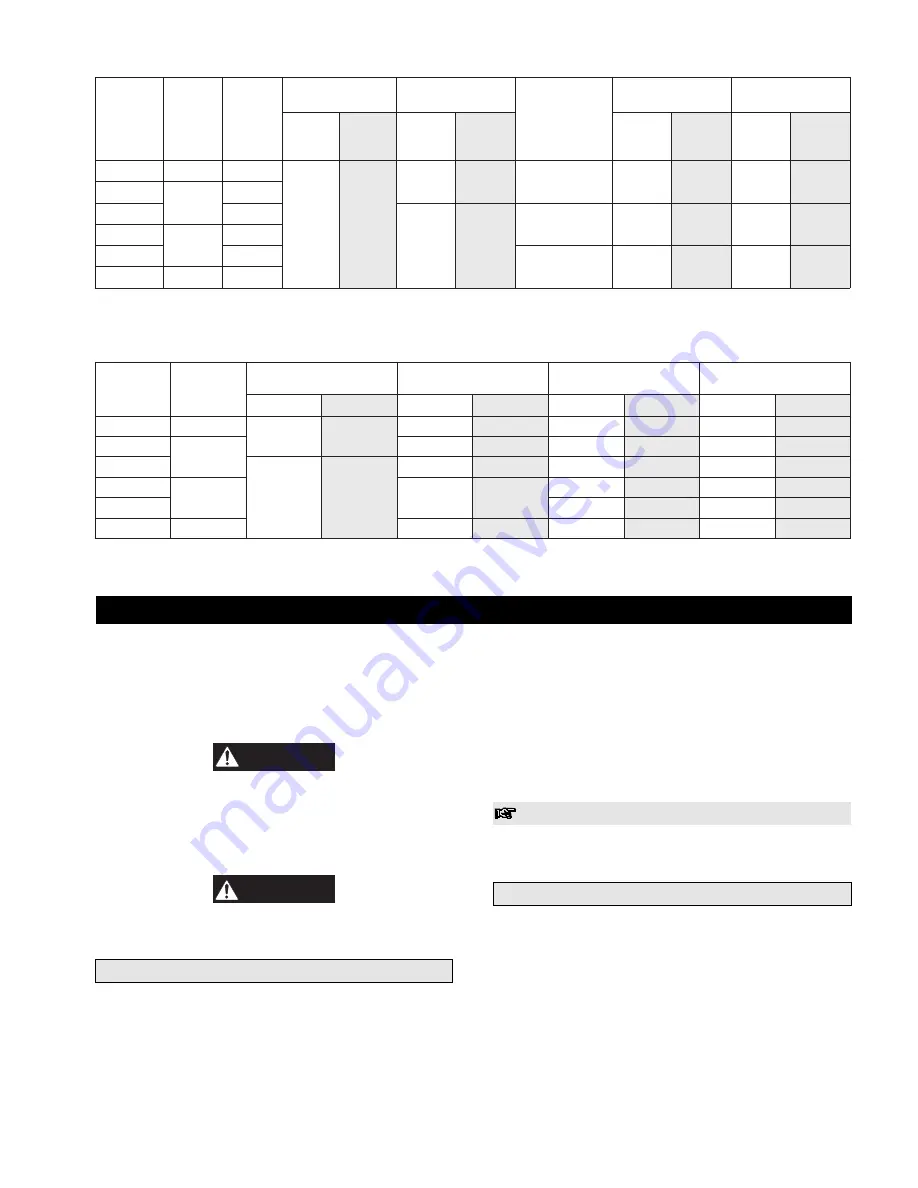

Air System

The supply air must be clean, lubricated and free from moisture.

A minimum of 58 psi (4 bar/400 kPa) at the hoist motor is

required to provide rated hoist capacity. Air inlet port size for

LCA015S and LCA030D units is 1/2 in. BSP. On all other units

the inlet port size is 3/4 in. BSP.

Air Lines

The inside diameter of the hoist air supply lines must not be

smaller than 3/4 in. (19 mm). Before making final connections,

all air supply lines should be purged before connecting to

s

n

o

i

t

a

c

i

f

i

c

e

p

S

t

s

i

o

H

l

e

d

o

M

d

e

t

a

R

y

t

i

c

a

p

a

C

c

i

r

t

e

m

s

n

o

t

d

a

o

L

n

i

a

h

C

s

l

l

a

F

e

r

u

s

s

e

r

P

w

o

l

F

r

i

A

e

z

i

S

n

i

a

h

C

m

m

n

i

a

h

C

f

o

.

t

W

.

t

W

t

e

N

t

i

n

U

n

i

a

h

C

t

u

o

h

t

i

w

i

s

p

r

a

b

/

t

f

u

c

n

i

m

/

m

u

c

n

i

m

r

e

p

)

b

l

(

t

f

r

e

p

e

r

t

e

m

)

g

k

(

s

b

l

g

k

S

5

1

0

A

C

L

5

.

1

1

8

5

4

3

5

5

.

1

4

2

x

8

1

0

.

1

5

.

1

4

8

8

3

D

0

3

0

A

C

L

3

2

S

0

3

0

A

C

L

1

1

7

2

6

3

x

3

1

9

5

.

2

5

8

.

3

0

3

1

9

5

D

0

6

0

A

C

L

6

2

S

0

6

0

A

C

L

1

5

4

x

6

1

6

8

.

3

5

7

.

5

3

1

2

7

9

D

0

2

1

A

C

L

2

1

2

e

r

u

s

s

e

r

P

r

i

A

)

r

a

b

4

(

i

s

p

8

5

t

a

e

c

n

a

m

r

o

f

r

e

P

t

s

i

o

H

t

s

i

o

H

l

e

d

o

M

d

e

t

a

R

y

t

i

c

a

p

a

C

s

n

o

t

c

i

r

t

e

m

w

o

l

F

r

i

A

d

e

e

p

S

g

n

i

t

f

i

L

.

x

a

M

d

a

o

L

d

e

t

a

R

h

t

i

w

d

e

e

p

S

g

n

i

r

e

w

o

L

.

x

a

M

d

a

o

L

d

e

t

a

R

h

t

i

w

d

e

e

p

S

.

x

a

M

d

a

o

L

o

N

h

t

i

w

n

i

m

/

t

f

u

c

n

i

m

/

m

u

c

n

i

m

/

t

f

n

i

m

/

m

n

i

m

/

t

f

n

i

m

/

m

n

i

m

/

t

f

n

i

m

/

m

S

0

5

1

A

C

L

5

.

1

3

5

5

.

1

2

.

8

5

.

2

1

2

4

.

6

1

.

5

1

6

.

4

D

0

3

0

A

C

L

3

4

2

.

1

5

.

0

1

2

.

3

5

.

7

3

.

2

S

0

3

0

A

C

L

6

.

0

7

2

6

.

6

2

3

2

7

8

.

4

1

5

.

4

D

0

6

0

A

C

L

6

3

.

3

1

5

.

1

1

5

.

3

2

.

7

2

.

2

S

0

6

0

A

C

L

8

.

9

3

2

.

5

6

.

1

D

0

2

1

A

C

L

2

1

5

.

6

1

5

.

0

9

.

4

5

.

1

6

.

2

8

.

0

Summary of Contents for LCA015

Page 26: ...25 SERVICE NOTES ...

Page 27: ...26 SERVICE NOTES ...

Page 31: ...30 LCA030S AND LCA060D HOIST ASSEMBLY PARTS DRAWING 3 and 6 ton Hoist Capacities Dwg MHP1464 ...

Page 33: ...32 LCA060S AND LCA120D HOIST ASSEMBLY PARTS DRAWING 6 and 12 ton Hoist Capacities Dwg MHP1465 ...

Page 50: ...49 SERVICE NOTES ...