11

(Dwg. MHP0111)

3.

HOOK LATCH. Make sure hook latch is present and

operating. Replace if necessary.

CAUTION

• Do not use hoist if hook latch is missing or damaged.

4.

CONTROLS. During operation of the hoist, verify that

response to pendant is quick and smooth. Ensure

controls return to neutral when released. If hoist responds

slowly or movement is unsatisfactory, do not operate the

hoist until all problems have been corrected.

5.

AIR SYSTEM. Visually inspect all connections, fittings,

hoses and components for indication of air leaks. Repair

any air leaks found. Check and clean the filter.

6.

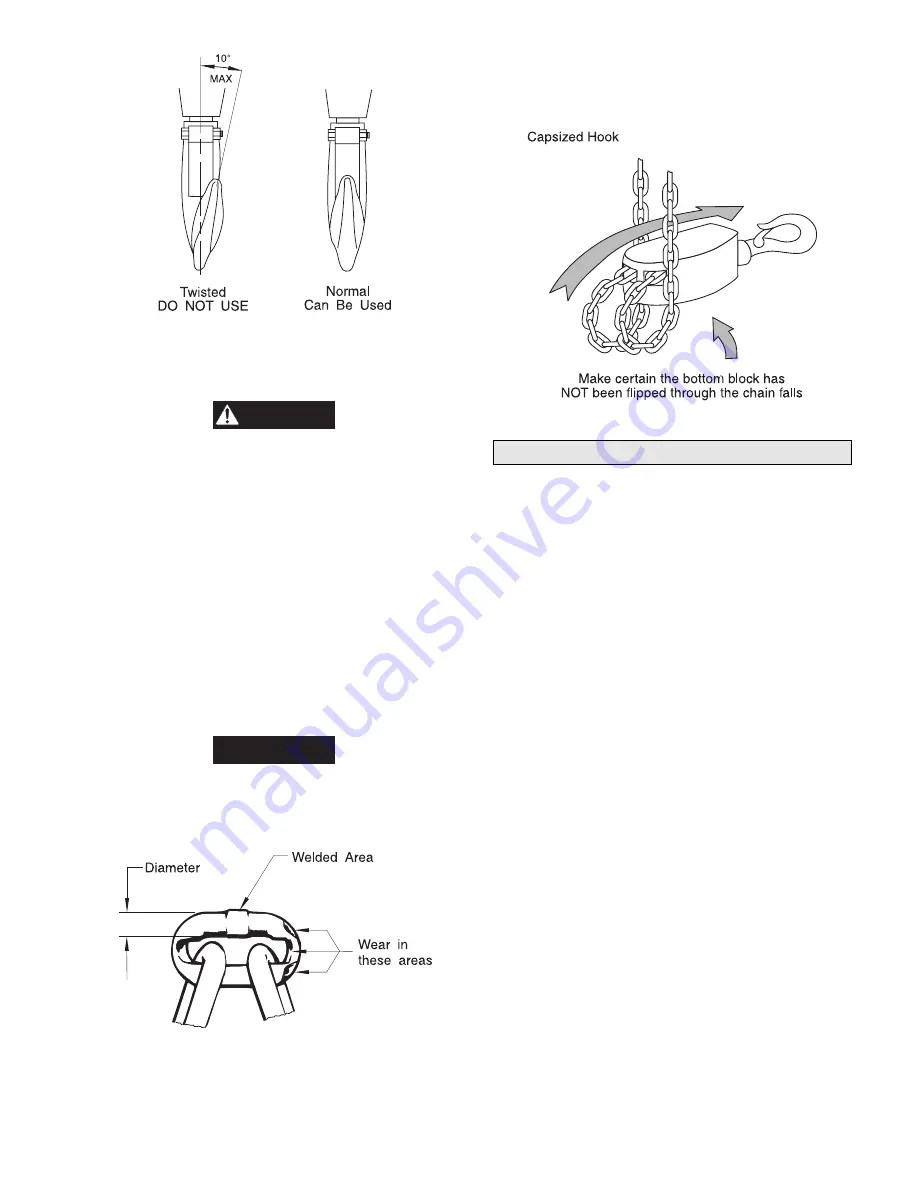

LOAD CHAIN. Examine each of the links for bending,

cracks in weld areas or shoulders, traverse nicks and

gouges, weld splatter, corrosion pits, striation (minute

parallel lines) and chain wear, including bearing surfaces

between chain links. Refer to Dwg. MHP0102. Replace a

chain that fails any of the inspections. Check chain

lubrication and lubricate if necessary. Refer to "Load

Chain" in the "LUBRICATION" section.

NOTICE

• The full extent of load chain wear cannot be determined by

visual inspection. At any indication of load chain wear,

inspect the chain and chain wheel in accordance with

instructions in "Periodic Inspection."

(Dwg. MHP0102)

7.

LOAD CHAIN REEVING. Ensure welds on standing links

are away from load sheave. Reinstall chain if necessary.

Make sure chain is not capsized, twisted or kinked. Adjust

as required. Refer to Dwg. MHP0043.

(Dwg. MHP0043)

Periodic Inspection

According to ASME B30.16, frequency of periodic inspection

depends on severity of usage:

NORMAL

HEAVY

SEVERE

yearly

semiannually

quarterly

Disassembly may be required for HEAVY or SEVERE usage.

Keep accumulative written records of periodic inspections to

provide a basis for continuing evaluation. Inspect all the items in

"Frequent Inspection." Also inspect the following:

1.

FASTENERS. Check all rivets, split pins, capscrews and

nuts. Replace if missing or tighten if loose.

2.

ALL COMPONENTS. Inspect for wear, damage,

distortion, deformations and cleanliness. If external

evidence indicates the need, disassemble. Check gears,

shafts, bearings, sheaves, chain guides, springs and covers.

Replace worn or damaged parts. Clean, lubricate and

reassemble.

3.

HOOKS. Inspect hooks carefully for cracks using magnetic

particle or other suitable non-destructive method. Inspect

hook retaining parts. Tighten or repair if necessary.

4.

LOAD CHAIN SPROCKET. Check for damage or

excessive wear. Replace if necessary. Observe the action of

the load chain feeding through the hoist. Do not operate a

hoist unless the load chain feeds through the hoist and hook

block smoothly and without audible clicking or other

evidence of binding or malfunctioning.

5.

MOTOR. If performance is poor, disassemble the motor

and check for wear or damage to bearings and shafts. The

parts should be cleaned, lubricated and reassembled.

Replace worn or damaged parts.

6.

BRAKE. Raise a load equal to the rated capacity of the

hoist a few inches (cms) off the floor. Verify hoist holds the

load without drift. If drift occurs, disassemble. Remove the

brake discs as described in the "MAINTENANCE" section.

Check and clean the brake parts each time the hoist is

disassembled. Replace the brake discs if the grooves are no

longer visible.

7.

SUPPORTING STRUCTURE. Check for distortion, wear

and continued ability to support a load.

Summary of Contents for LCA015

Page 26: ...25 SERVICE NOTES ...

Page 27: ...26 SERVICE NOTES ...

Page 31: ...30 LCA030S AND LCA060D HOIST ASSEMBLY PARTS DRAWING 3 and 6 ton Hoist Capacities Dwg MHP1464 ...

Page 33: ...32 LCA060S AND LCA120D HOIST ASSEMBLY PARTS DRAWING 6 and 12 ton Hoist Capacities Dwg MHP1465 ...

Page 50: ...49 SERVICE NOTES ...