14

LUBRICATION

To ensure continued satisfactory operation of the hoist, all

points requiring lubrication must be serviced with the correct

lubricant at the proper time intervals indicated for each

assembly. Correct lubrication is one of the most important

factors in maintaining efficient operation.

The lubrication intervals recommended in Table 6 are based on

intermittent operation of the hoist eight hours each day, five

days per week. If the hoist is operated almost continuously, or

for more than eight hours each day, or under severe conditions,

more frequent lubrication will be required.

6

e

l

b

a

T

t

n

e

n

o

p

m

o

C

l

e

v

e

L

e

g

a

s

U

y

b

y

c

n

e

u

q

e

r

F

n

o

i

t

a

c

i

r

b

u

L

e

r

e

v

e

S

y

v

a

e

H

l

a

m

r

o

N

n

i

a

h

C

d

a

o

L

y

l

i

a

D

y

l

k

e

e

W

e

g

a

s

U

t

A

d

n

a

k

o

o

H

h

c

t

a

L

k

o

o

H

y

l

i

a

D

y

l

k

e

e

W

e

g

a

s

U

t

A

e

s

a

C

r

a

e

G

y

l

r

a

e

Y

s

r

a

e

Y

3

y

r

e

v

E

y

r

a

s

s

e

c

e

n

n

U

Lubricant types and change intervals are based on operation in

an environment relatively free of dust, moisture and corrosive

fumes. Use only those lubricants recommended. Other lubricants

may affect performance of the hoist. Approval for the use of

other lubricants must be obtained from your Ingersoll-Rand

Technical Support Department or distributor. Failure to observe

this precaution may result in damage to the hoist and/or its

associated components.

Whenever a hoist is disassembled for overhaul or replacement of

parts, lubricate as follows:

Brake and Gear Assemblies

The gear and brake assemblies share a common oil bath. On

larger capacity hoists, the output shaft from the motor is offset

and utilizes a pinion gear to drive the sun gear. These gears

operate in the motor casing oil bath. Refer to Table 7 for oil

quantities. Refer to Dwg. MHP1473 for position of gear box oil

drain plugs.

(Dwg. MHP1473)

7

e

l

b

a

T

l

e

d

o

M

g

n

i

s

a

C

r

a

e

G

g

n

i

s

a

C

r

o

t

o

M

s

t

n

i

P

l

m

s

t

n

i

P

l

m

d

n

a

S

5

1

0

A

C

L

D

0

3

0

A

C

L

3

.

0

0

5

1

A

/

N

A

/

N

d

n

a

S

0

3

0

A

C

L

D

0

6

0

A

C

L

8

.

0

0

0

4

4

.

0

0

5

1

d

n

a

S

0

6

0

A

C

L

D

0

2

1

A

C

L

6

.

1

0

5

7

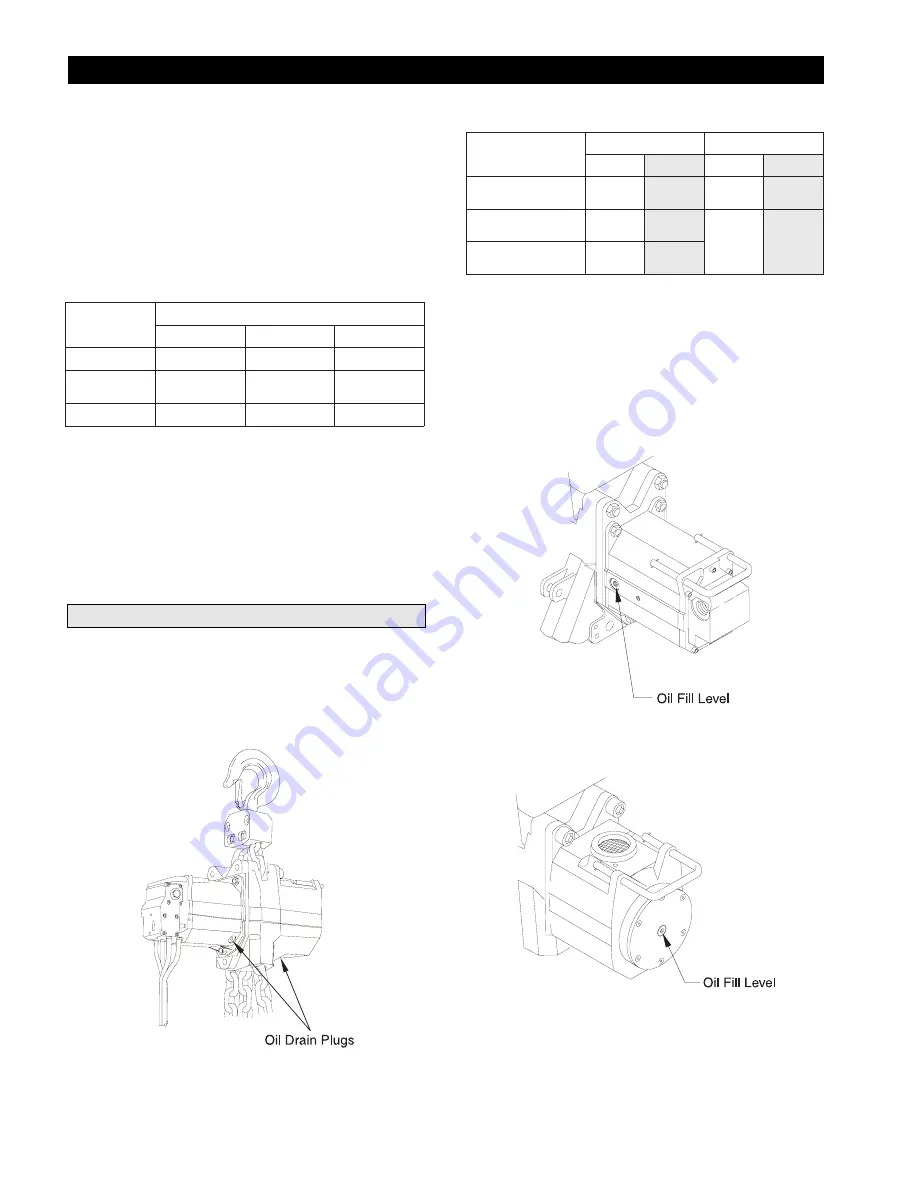

LCA015S and LCA030D Hoists Oil Fill Level Position

Fill to the level of the plug on the side of the gear housing.

LCA030S and Larger Hoists Oil Fill Level Position

Fill to the level of the plug on the side of the motor housing and

on the gear end in the center of the brake end cover. Refer to

Dwgs. MHP1439 and MHP1440.

Oil Fill Level Position on Motor Housing

(Dwg. MHP1439)

Oil Fill Level Position on Brake End Cover

(Dwg. MHP1440)

Summary of Contents for LCA015

Page 26: ...25 SERVICE NOTES ...

Page 27: ...26 SERVICE NOTES ...

Page 31: ...30 LCA030S AND LCA060D HOIST ASSEMBLY PARTS DRAWING 3 and 6 ton Hoist Capacities Dwg MHP1464 ...

Page 33: ...32 LCA060S AND LCA120D HOIST ASSEMBLY PARTS DRAWING 6 and 12 ton Hoist Capacities Dwg MHP1465 ...

Page 50: ...49 SERVICE NOTES ...