23

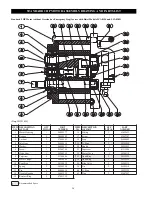

4HP with Emergency Stop and Overload

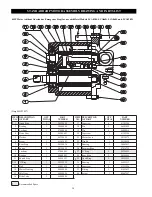

Refer to Dwg. MHP1455.

Follow steps 1 through 12 immediately above, for initial motor

assembly.

Assembly of Emergency Stop and Overload options:

1.

Ensure dowels (19) are installed in motor cover (21).

2.

Lubricate and position 'O' rings (27) and stops (28) on

motor cover.

3.

Assemble items (37), (38), (39) and (44) on screw (43).

Install screw with parts into motor cover. Screw (35), (37)

and (38) on opposite end and tighten. Use Loctite

®

243 on

threads.

4.

Install spring (42) and 'O' ring (46) in cover (45) and

assemble on motor cover. Secure with three capscrews (41).

Apply Loctite

®

243 to threads.

5.

Install diaphragm (36) on opposite side.

6.

Grease and install ball (50), spring receiver (51) and spring

(52) in motor cover.

7.

Assemble items (53), (54) and (55) to diaphragm (59).

Ensure parts are assembled from the correct side. There is

one extra hole in addition to the four capscrew holes. The

extra hole must align with the port hole in the motor cover

and cover (34).

8.

Install cover (34) with capscrews (32) using Loctite

®

243

on the threads. Torque capscrews to 7.5 ft-lbs (5.5 Nm).

9.

Install seal washer (57) in cover (34) with plug (58).

10. Thread nut (48) onto screw (47) and install with seal ring

(49).

11. Refer to Overload Device Adjustments in the

"MAINTENANCE" section to reestablish settings.

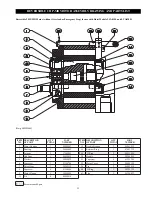

Reduction Housing

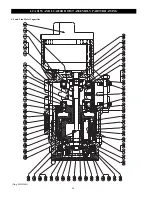

LCA015S and LCA030D Hoists

Refer to Dwg. MHP1462.

1.

Install 'O' ring (43) in gear housing (23). Ensure two dowel

pins (22) are in place in the gear housing and are

undamaged.

2.

Carefully install ring gear (20) in gear housing making sure

dowel pins are aligned with the holes in the ring gear. Tap

down until seated.

3.

Install bearing (40) on planetary support (19).

4.

Install two bearings (46) with a spacer (45) between, in

each planetary gear (44).

5.

Install planetary gears with bearings into planetary support

(19) and locate with satellite axles (47). Ensure planet gears

(44) are installed with the smaller gear head diameter

nearest the side of the planetary support (19) with the

timing notches.

6.

Rotate satellite axles to allow installation of bearing (17).

7.

Install bearing (39) and secure with retainer ring (32).

8.

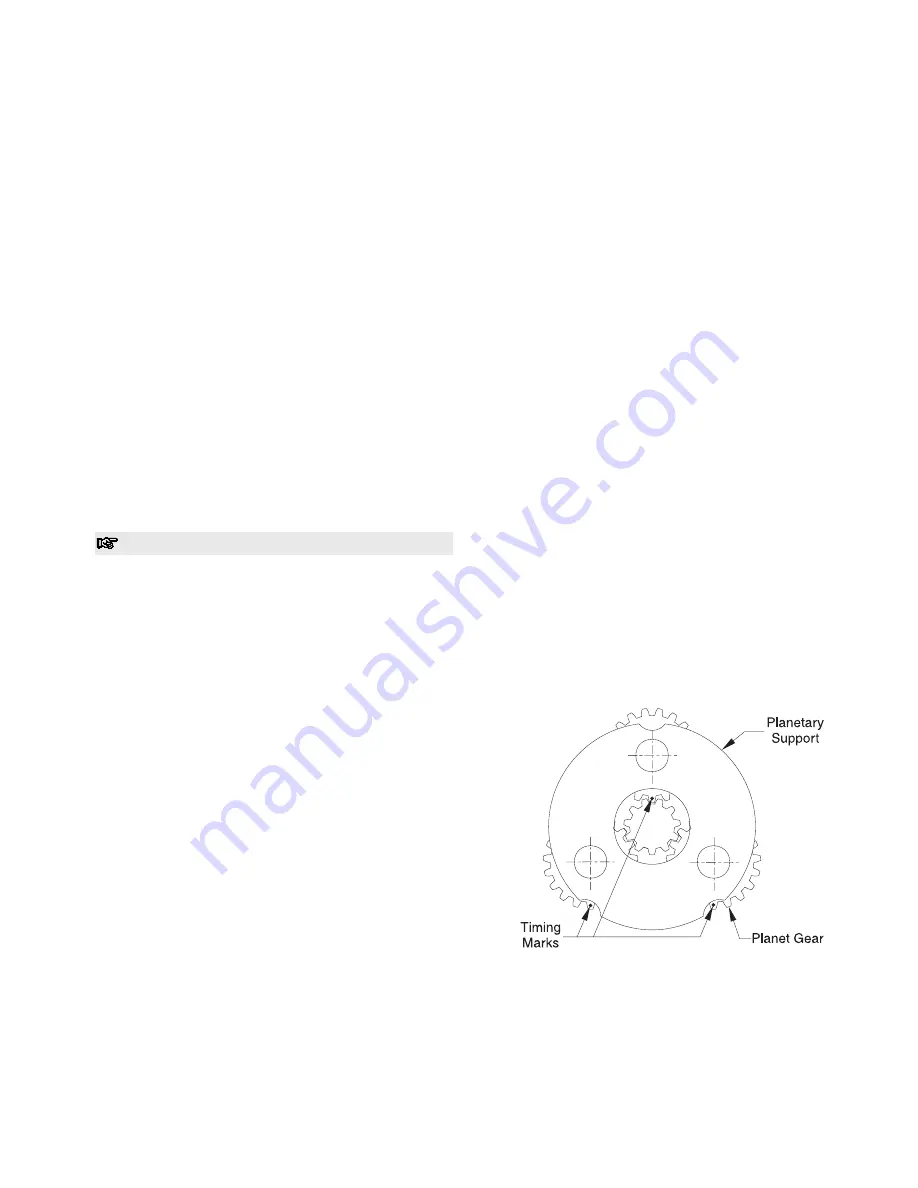

Time planetary gears as shown in drawing MHP1406. Use

of a separate ring gear tool to maintain gear position during

installation of planetary assembly is helpful. Install

planetary assembly and tap down until planetary assembly

is fully seated.

9.

Install pinion (21). Tap into position until seated against

bearing (39).

10. Install ring gear (18).

11. Lubricate and install 'O' ring (43) in gear cover (48). Install

oil seal (13) with lip toward planetary support.

12. Install gear cover (48). Attempt to locate the puller holes at

the top and bottom just off vertical. This may aid

disassembly at some later date. Install pinion (11).

13. Refer to "Brake Assembly" for information on assembling

the remaining brake parts.

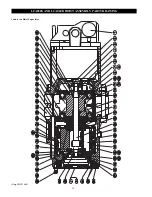

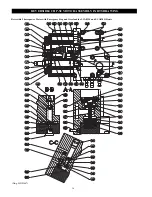

LCA030S and LCA060D Hoists

Refer to Dwg. MHP1464.

1.

Install 'O' ring (42) in gear housing (31). Ensure three

dowel pins (40) are in place in the gear housing (31) and

are undamaged.

2.

Install new 'O' ring (47) on ring gear (45).

3.

Install friction and steel discs. Begin with a friction disc

(27) and then alternate with a steel disc (28) until discs are

used. Locate friction disc tabs in slots provided in gear

housing.

4.

Install bearing (43) in ring gear and secure with retainer

ring (41).

5.

Carefully install ring gear in gear housing making sure

dowel pins are aligned with the holes in the ring gear. Tap

down until retainer ring groove in gear housing bore, is

visible. Use a clamp to further pull ring gear into position

compressing 'O' ring (42). Install retainer ring (48). Ensure

retainer ring is fully seated, then release clamp.

6.

Install sun gear (20) and tap into position through bearing

(43) until seated.

7.

Turn gear housing over and support to avoid damaging the

sun gear. Align tabs on steel discs (28) and install brake

sleeve (39) on sun gear spline. Secure in position with

retainer ring (36).

8.

Install two bearings (21) with a spacer (22) between, in

each planetary gear (24).

9.

Install planet gears with bearings into planetary support

(46) and locate with planet axles (23). Place one bearing

(25) and one thrust ring (26) on each side of the planetary

gears. Bearings (25) must contact inside face of planetary

support and thrust rings (26) must contact planet gears.

Ensure planet gears (24) are installed with the smaller gear

head diameter nearest the side of the planetary support (46)

with the timing notches.

10. Rotate planet axles to allow installation of bearing (44) on

the brake side. Pin punch around bearing to hold in place

during assembly into gear housing (31).

11. Time gears as shown in drawing MHP1406. Using a

separate ring gear tool to maintain gear position during

installation of planetary assembly is helpful. Tap down

until planetary assembly is fully seated.

(Dwg. MHP1406)

12. Install oil seal (57) and 'O' rings (54) and (56) on gear cover

(55). Seal lip must be toward gear side.

13. Set drive pinion (17) on bench with the splined end up.

Install gear cover on drive pinion with the threaded jacking

holes toward the bench.

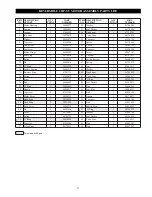

Summary of Contents for LCA015

Page 26: ...25 SERVICE NOTES ...

Page 27: ...26 SERVICE NOTES ...

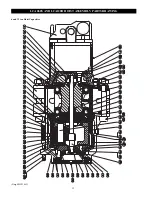

Page 31: ...30 LCA030S AND LCA060D HOIST ASSEMBLY PARTS DRAWING 3 and 6 ton Hoist Capacities Dwg MHP1464 ...

Page 33: ...32 LCA060S AND LCA120D HOIST ASSEMBLY PARTS DRAWING 6 and 12 ton Hoist Capacities Dwg MHP1465 ...

Page 50: ...49 SERVICE NOTES ...