21

MAINTENANCE SECTION

2. If the Lower Arbor Bearing (29) is being installed, it

is necessary to note the identification marks on the

Lower Arbor Bearing. The side of the Bearing having

black stains or black hash marks on the side of the

inner and outer races is opposite the flush ground

side.

3. Using your hand, push the Lower Arbor Bearing,

flush ground side inward, into the recess at the ma-

chined end of the Angle Head.

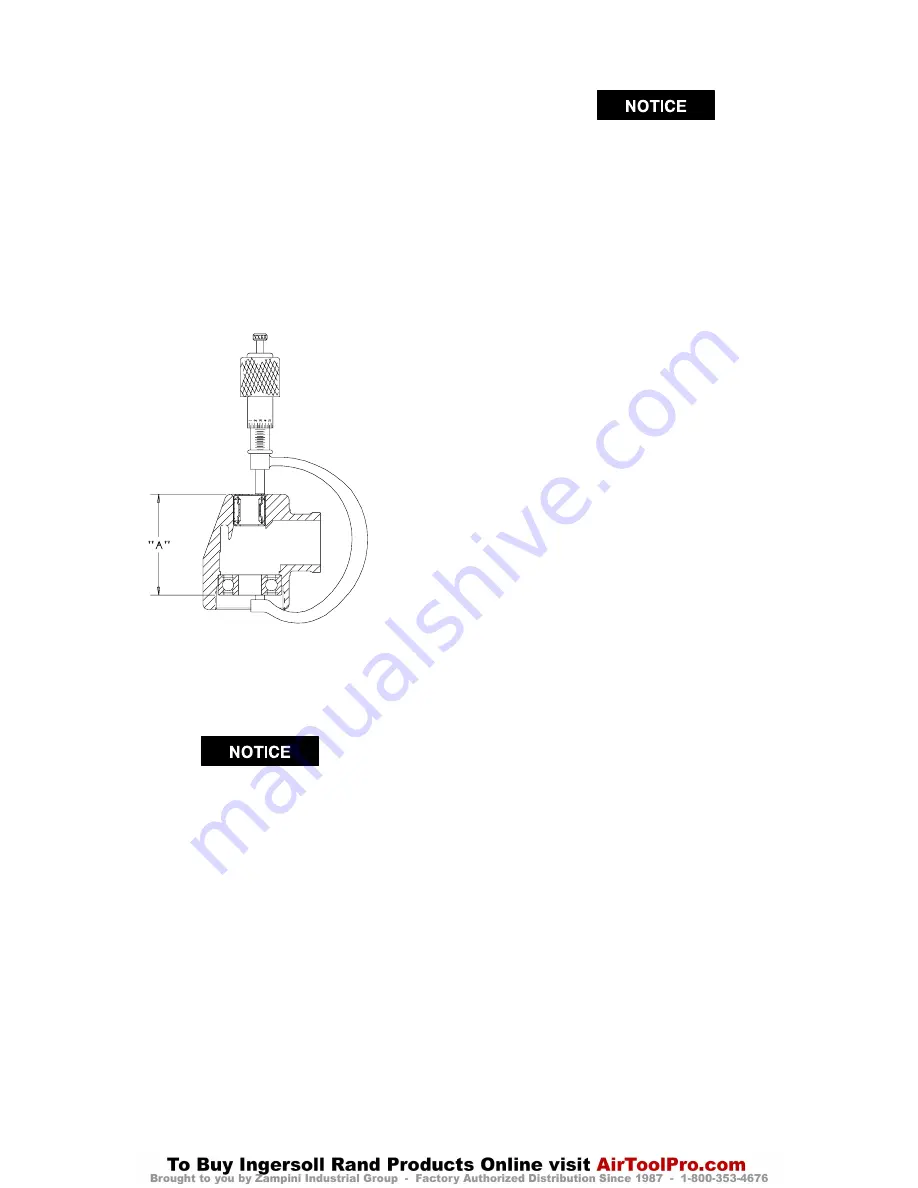

4. Using a 2” micrometer, take a measurement from the

inner ring of the Lower Arbor Bearing to the stamped

or closed end of the Upper Arbor Bearing.

See Dwg. TPD687.

(Dwg. TPD687)

Minimum

Dimension

“A”

in mm

1.36 34.65

Maximum

Dimension

“A”

in mm

1.38 35.00

5. Additional pressing of the Upper Arbor Bearing may

be required to finally attain the correct dimension as

indicated in the table above.

6. Remove the Lower Arbor Bearing.

In the following step, make certain any shims in-

cluded with the Lower Arbor Bearing are installed

onto the Arbor between the Bevel Gear (21) and

the Bearing.

7. Using a sleeve that contacts the inner ring of the Low-

er Arbor Bearing, press the Bearing, flush ground

side of the Bearing trailing onto the Arbor (31).

8. Slide the Bevel Gear, geared face trailing, onto the

small threaded end of the Arbor, aligning the integral

keys of the gear with the slotted keyways in the

Arbor.

*

Product of National Starch and Chemical Corporation.

** Product of N.D. Industries.

The Bevel Gear and Bevel Pinion are specially

matched sets.

Replace these parts only as a

matched set.

9. Thoroughly clean the small threads on the Arbor

above the Bevel Gear and the threads in the Bevel

Gear Nut (28).

10. Apply a thin coat of Permalock HM118* to the

threads of the Bevel Gear Nut and the Nut threads on

the Arbor. Thread the Bevel Gear Nut onto the Arbor

to retain the Bevel Gear and tighten the Nut to 10 to

12 ft–lb (13.5 to 16.2 Nm) torque. Grease the Bevel

Gear with 1.5 cc of Ingersoll–Rand No. 67 Grease.

11. Form the Wick (27) into a horseshoe shape and insert

it into the Angle Head. Push the Wick into the open-

ing until it is compressed approximately 0.030” below

the bevel gear bore. Soak the Wick with approximate-

ly 1.5 cc of Ingersoll–Rand No. 63 Oil. Do no substi-

tute any other oil.

12. Carefully grasp the assembled motor in leather– cov-

ered or copper–covered vise jaws with the Throttle

Lever downward.

13. Install the motor Clamp Nut (24), threaded end trail-

ing, onto the motor end of the Angle Head. Spread the

Clamp Spacer (23) and install it on the motor end of

the Angle Head against the Clamp Nut.

14. Position the output end of the Angle Head upward and

opposite with the Throttle Lever and thread the

Clamp Nut onto the Motor Housing. Using the Clamp

Nut Wrench (52), tighten the Nut to 20 to 25 ft–lb

(27 to 34 Nm) torque. This is a left–hand thread, turn

counterclockwise to tighten.

15. Insert the assembled Arbor into the Angle Head, bevel

gear end first, making sure the teeth on the Bevel

Gear and Pinion mesh. Rotate the Arbor manually to

determine that they are rotating smoothly.

16. Thoroughly clean the internal threads of the Angle

Head and the threads on the Arbor Bearing Cap (30).

17. Carefully apply a uniform coat of Vibra–Tite VC3

No. 205 ** to both sets of threads and allow the com-

pound to cure for 10 to 20 minutes.

18. Using the Arbor Bearing Cap Wrench (53), install the

Arbor Bearing Cap and tighten to 12 to 15 ft–lb (16.2

to 20.3 Nm) torque. The Bearing Cap has a left–hand

thread: turn counterclockwise to install.