3

ADJUSTMENTS

DO NOT SUBSTITUTE ANY OTHER FLUID.

Failure to use the impulse mechanism fluid provided

could damage the tool, increase maintenance and

decrease performance. Use only clean fluid in these

tools.

(Dwg. TPD1265)

10. Submerge the fill opening in the remainder of the fluid,

and using a wrench, rotate the Drive Shaft to purge any

remaining air from the system.

11. Remove the mechanism from the fluid and use the Tee

Wrench to push the Piston Stop Assembly slowly

downward until fluid flows from the fill opening.

12. Thread the Oil Plug with the Oil Plug Seal and Seal

Support into the mechanism until it is snug.

13. Using a 2 mm hex wrench on the Model 900P–EU and a

1.5 mm hex wrench on all other models, turn the Torque

Adjustment Screw clockwise until it stops. This is the

maximum torque position.

14. Wipe the outside of the mechanism dry and clean and

remove the Oil Chamber Plug. Using the syringe,

withdraw 0.35 cc of fluid from 500P–EU and

500PQ1–EU models, 0.50 cc of fluid from 700P–EU

models and 0.85 cc from 900P–EU models.

15. Install the Oil Chamber Plug and tighten it between 20

and 25 in–lb (2.3 and 2.8 Nm) torque.

16. Position a new Hammer Case Gasket on the Motor

Housing and install the assembled mechanism on the

rotor shaft.

17. Place the Hammer Case Cover over the Drive Shaft

against the Housing and Gasket. Install the three Hammer

Case Cap Screws and Lock Washers. Tighten

each Screw between 45 an 50 in–lb (5.1 and 5.6 Nm)

torque.

18. Install the Rubber Housing Boot on the tool.

19. For Model 500PQ1–EU, install the Bit Retaining Ball in

the hole in the Drive Shaft and capture it by sliding the

Bit Retaining Sleeve, small bore first, onto the Drive

Shaft.

20. For Model 500PQ1–EU, install the Retaining Sleeve

Spring and Spring Seat, counterbored end trailing, over

the drive shaft hub and into the Sleeve.While

compressing the Spring, with a thin blade screwdriver

against the Seat, install the Retaining Ring in the annular

groove in the hub of the Drive Shaft.

PLACING TOOL IN SERVICE

LUBRICATION

Ingersoll–Rand No. 50

Ingersoll–Rand No. 67

Ingersoll–Rand Fluid Part

No. EQ106S–400–1

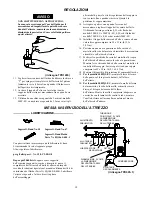

Always use an air line lubricator with these tools.

We recommend the following Filter–Lubricator–Regulator

Unit:

For International – No. C18–C3–FKG0

After each 20,000 cycles, or as experience indicates, drain

and refill the Impulse Unit Drive Assembly as instructed

in this manual using the Fluid Replacement Kit (Part

No. EQ106S–K400). Lubricate the hex drive and the output

shaft before assembly.

MAIN LINES 3 TIMES

AIR TOOL INLET SIZE

TO

AIR

SYSTEM

TO

AIR

TOOL

LUBRICATOR

REGULATOR

FILTER

BRANCH LINE 2 TIMES

AIR TOOL INLET SIZE

DRAIN REGULARLY

COMPRESSOR

(Dwg. TPD905–1)