17

INS

TALLER

US

ER

MAINTEN

AN

CE TECHNI

CI

AN

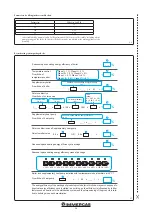

3.15 CASING REMOVAL.

To facilitate boiler maintenance the casing can be

completely removed as follows (Fig. 3-4):

- Remove frame (1) grasping the edges and pul-

ling towards oneself as indicated by the arrow.

- Loosen the 2 front screws (2) and the 2 screw

fasteners (3) below on the casing o (4).

- Pull the casing (4) towards yourself and

upwards at the same time in order to detach it

from the upper hooks.

3.16 YEARLY APPLIANCE CHECK AND

MAINTENANCE.

The following checks and maintenance should

be performed at least once a year.

- Clean the flue side of the heat exchanger.

- Clean the main burner.

- Visually check the fume hood for deterioration

or corrosion.

- Check correct lighting and functioning.

- Check correct calibration of the burner in

domestic hot water and heating phases.

- Check correct functioning of control and

adjustment devices and in particular:

- the intervention of main electrical switch

positioned outside of the boiler;

- system control thermostat intervention;

- domestic hot water control thermostat inter-

vention.

- Check that the internal system is properly

sealed according to specifications.

- Check the intervention of the device against no

gas ionization flame control. Intervention time

must be less than 10 seconds.

- Visually check for water leaks or oxidation

from/on connections.

- Visually check that the water safety drain valve

is not blocked.

- Check that, after discharging system pressure

and bringing it to zero (read on boiler mano-

meter), the expansion vessel load is at 1.0 bar.

- Check that the system static pressure (with

system cold and after refilling the system by

means of the filling valve) is between 1 and 1.2

bar.

- Check visually that the safety and control

devices have not been tampered with and/or

shorted, in particular:

- temperature safety thermostat;

- water pressure switch;

- flue exhaust control thermostat.

- Check the condition and integrity of the elec-

trical system and in particular:

- electrical power cables must be inside the

whipping;

- there must be no traces of blackening or

burning.

N.B.

: in addition to yearly maintenance, the ther-

mal system must also be checked, with frequency

and procedures that comply with the provisions

of the technical regulations in force.

Summary of Contents for Nike Star 24 4 ErP

Page 18: ...18 3 4 3 2 2 4 1 INSTALLER USER MAINTENANCE TECHNICIAN ...

Page 27: ...27 ...