14

3-2

6

1

3

2

7

6

5

4

5

5

6

10

9

9

8

8

8

10

10

8

9

11

11

9

10

INS

TALLER

US

ER

MAINTEN

AN

CE TECHNI

CI

AN

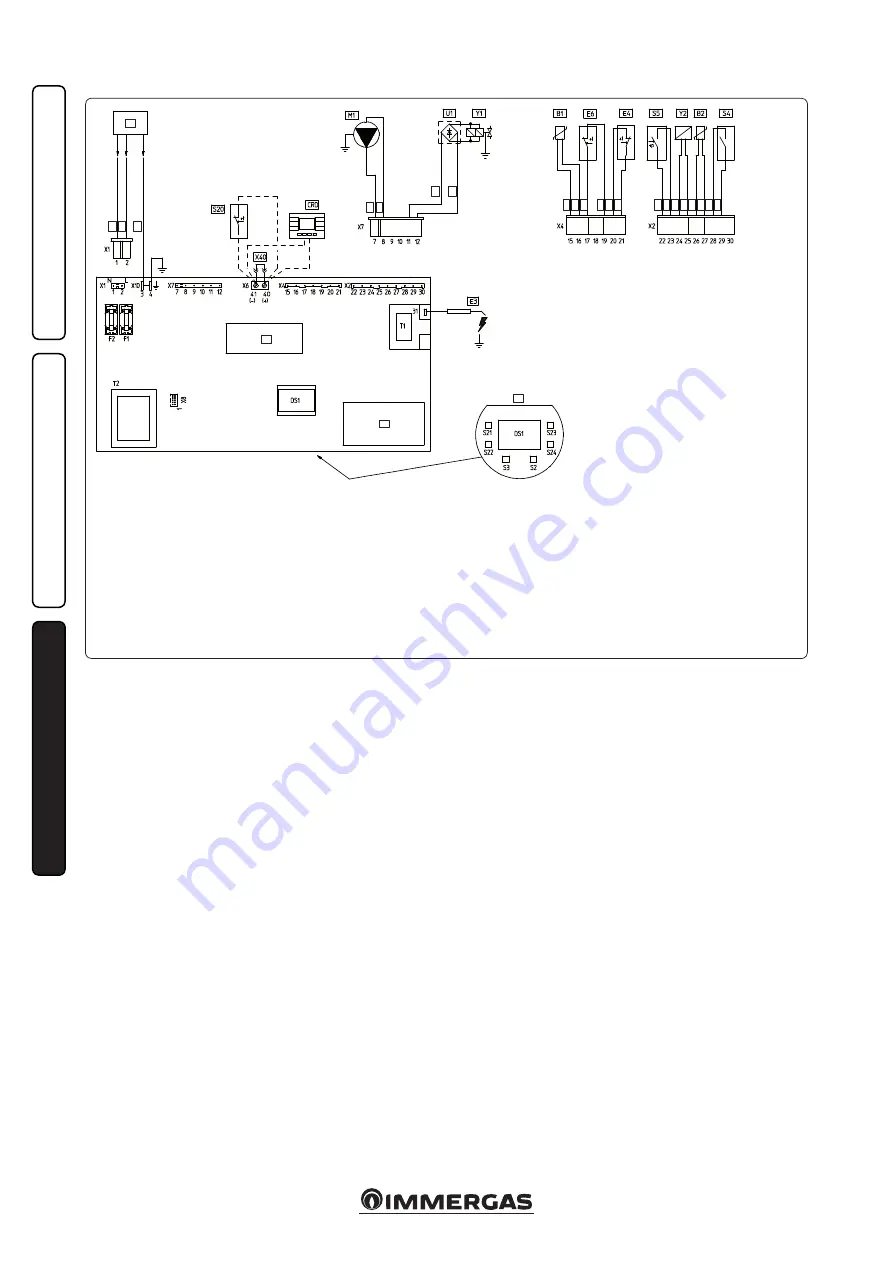

Key:

B1 - Delivery probe

B2 - Domestic hot water probe

CRD - Digital Mini Remote Control (optional)

DS1 - Display

E3 - Ignition and detection electrodes

E4 - Safety thermostat

E6 - Flue safety thermostat

F1 - Phase fuse

3.2 WIRING DIAGRAM.

F2 - Neutral fuse

M1 - Boiler circulating pump

S2 - Selector switch functioning

S3 - Reset block keys

S4 - Domestic hot water flow switch

S5 - System pressure switch

S20 - Room thermostat (optional)

S21 - Domestic hot water temperature

increase key

S22 - Domestic hot water temperature

reduce key

S23 - Heating temperature increase key

S24 - Heating temperature reduce key

T1 - Switch-on transformer

T2 - Boiler board transformer

U1 - Rectifier inside the gas valve

connector (Only available on

Honeywell gas valves)

X40 - Room thermostat jumper

Y1 - Gas valve

Y2 - Gas valve modulator

1 - User interface

2 - N.B.: The user interface is on the

welding side of the boiler board

3 - The X6 connector is used for

automatic inspection

4 - 230 Vac 50Hz power supply

5 - Blue

6 - Brown

7 - Yellow/Green

8 - Black

9 - Grey

10 - White

11 - Red

The boiler is designed for application of a room

thermostat (S20), an On/Off room chrono-

thermostat, a program timer or a Digital Mini

Remote Control (CRD). Connect it to clamps

40 –41 eliminating jumper X40.

3.3 TROUBLESHOOTING.

N.B.:

Maintenance must be carried out by a

qualified company (e.g. Technical After-Sales

Assistance Service).

- Smell of gas. Caused by leakage from gas circuit

pipelines. Check sealing efficiency of gas intake

circuit.

- Irregular combustion (red or yellow flame).

When the burner is dirty or the boiler lamellar

pack is blocked. Clean the burner or the boiler

lamellar pack.

- Frequent activation of the temperature over-

load thermostat. It can depend on the lack of

water in the boiler, little water circulation in

the system or blocked pump. Check on the

manometer that the system pressure is within

established limits. Check that the radiator val-

ves are not closed and also the functionality of

the pump.

- The boiler produces condensate. This can be

caused by obstructions of the chimney or flues

with height or section not proportioned to the

boiler. It can also be determined by functioning

at boiler temperatures that are excessively low.

In this case, make the boiler run at higher

temperatures.

- Frequent interventions of the chimney safety

thermostat. This can be caused by obstructions

in the fumes circuit. Check the flue. The flue

may be obstructed or by height or section

not suitable for the boiler. Ventilation may be

insufficient (see room ventilation point).

- Presence of air in the system. Check opening

of the special automatic vent valve (Fig. 1-6).

Make sure the system pressure and expansion

vessel pre-charge values are within the set

limits; the pre-charge value for the expansion

vessel must be 1.0 bar, and system pressure

between 1 and 1.2 bar.

- Ignition block and Chimney block. (See par.

2.5 and 1.5 (electric connection).

- Low water flow: if, as a result of limescale (cal-

cium and magnesium), the domestic hot water

system does not work properly contact a qua-

lified technician for descaling e.g. Immergas

After-Sales Technical Service. Descaling must

be carried out on the domestic hot water side

of the bithermal heat exchanger in accordance

with good practice. To preserve integrity and

efficiency of the heat exchanger, a non corro-

sive descaler must be used. Cleaning must be

carried out without the use of tools which can

damage the heat exchanger.

3.4 CONVERTING THE BOILER TO

OTHER TYPES OF GAS.

If the boiler has to be converted to a different gas

type to that specified on the data plate, request

the relative conversion kit for quick and easy

conversion.

Boiler conversion must be carried out by a

qualified company (e.g. After-Sales Technical

Assistance Service).

To convert to another type of gas the following

operations are required:

- remove the voltage from the appliance;

- replace the main burner injectors, making sure

to insert the special seal rings supplied in the

kit, between the gas manifold and the injectors;

- apply voltage to the appliance;

- select using the boiler key, the gas parameter

type (P1) and select (

nG

) in case of Methane

supply or (

LG

) in the case of LPG

select gas parameter type (P2) in the case of

G110 gas supply;

- adjust the boiler nominal heat output;

- adjust the boiler nominal heat output in dome-

stic hot water phase;

- adjust the boiler nominal heat output in heating

phase;

- adjust (if necessary) the boiler maximum heat

output in heating phase;

- seal the gas flow rate regulation devices (if

settings are modified);

- after completing conversion, apply the sticker,

present in the conversion kit, near to the data-

plate. Using an indelible marker pen, cancel the

data relative to the old type of gas.

These adjustments must be made with reference

to the type of gas used, following that given in

the table (parag. 3.17).

Summary of Contents for Nike Star 24 4 ErP

Page 18: ...18 3 4 3 2 2 4 1 INSTALLER USER MAINTENANCE TECHNICIAN ...

Page 27: ...27 ...