13

3-1

INS

TALLER

US

ER

MAINTEN

AN

CE TECHNI

CI

AN

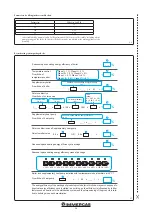

3.1 HYDRAULIC LAYOUT.

Key:

1 - Domestic hot water probe

2 - Domestic hot water flow switch

3 - Gas valve

4 - Flow limiter

5 - System draining valve

6 - Burner

7 - Rapid heat exchanger

8 - Fumes hood

9 - Flue safety thermostat

10 - System expansion vessel

11 - Delivery probe

12 - Safety thermostat

13 - Vent valve

14 - Boiler pump

15 - System pressure switch

16 - By-pass

17 - 3 bar safety valve

18 - System filling valve

G - Gas supply

AC - Domestic hot water outlet

AF - Domestic cold water inlet

R - System return

M - System delivery

3

BOILER START-UP.

(INITIAL CHECK)

To commission the boiler:

- ensure that the type of gas used corresponds to

boiler settings;

- check connection to a 230V-50Hz power

mains, correct L-N polarity and the earthing

connection;

- switch the boiler on and ensure correct ignition;

- make sure the gas maximum, intermediate

and minimum flow rate and pressure values

correspond to those given in the handbook

par. 3.17;

- check activation of the safety device in the event

of no gas, as well as the relative activation time;

- check activation of the main switch located

upstream from the boiler;

- check the existing draught during normal

functioning of the appliance, e.g. a draught

gauge positioned at the exit of the appliance

combustion products;

- check that there is no backflow of combustion

products into the room, even during functio-

ning of fans;

- ensure activation of all adjustment devices;

- seal the gas flow rate regulation devices (if

settings are modified);

- check the production of domestic hot water;

- check sealing efficiency of water circuits;

- check ventilation and/or aeration of the instal-

lation room where provided.

If even only one control inherent to safety gives a

negative result, do not start the system.

Summary of Contents for Nike Star 24 4 ErP

Page 18: ...18 3 4 3 2 2 4 1 INSTALLER USER MAINTENANCE TECHNICIAN ...

Page 27: ...27 ...