P

P

a

a

g

g

e

e

1

1

7

7

-

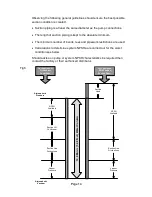

Ensure product is available at the inlet before starting the pump. This is

very important for pumps installed with un-flushed product seals, as these

sealing arrangements must never be allowed to run dry.

-

Before beginning operation, it is considered a good practice to

momentarily start/stop the pump to check the direction of rotation and

ensure that the pump is free of obstructions. Once this has been carried

out, begin operation keeping a visual check on suction and discharge

pressure gauges and monitor pump temperature and power absorbed

where possible.

3.5

Shutdown Procedure.

When shutting the pump down, stop the pump, close both the suction and

discharge valves and ensure that the necessary safety precautions are taken:

- The prime mover power source has been isolated.

-

If installed, flushed product seal auxiliary services have been isolated and

depressurised.

- Pump head and piping have been drained and purged.

3.6

Routine Maintenance – Non Atex units.

Grease

-

Check for any signs of lubricant leakage

-

Low maintenance gearbox, factory filled with EP 00 semi-fluid grease.

The grease should not require replacement during the lifetime of the

bearings or until 20,000 hours of operation.

Oil

-

Check oil levels regularly.

-

Change the oil every 12 months or 3000 operating hours, whichever is

the sooner.

For lubricant capacities and grades refer to section 5.3.

Seal Replacement Interval:

It is recommended that the Rotor Retainer O-ring seal is replaced every 12

months to maintain a bacteria-tight seal.

Rotor Retainer Seal Inspection:

Periodically inspect the Rotor Retainer O-ring seal for any discolouration,

nicks, or cracks. If any of the defects above are noticed, the O-ring seal must

be replaced. Inspection and replacement refer to the seal replacement

procedure.

W

W

A

A

R

R

N

N

I

I

N

N

G

G

W

W

A

A

R

R

N

N

I

I

N

N

G

G

Summary of Contents for Wright Flow Technologies RTP Series

Page 1: ...P Pa ag ge e 0 0 INSTALLATION OPERATION AND MAINTENANCE MANUAL FOR THE RANGE OF PUMPS...

Page 47: ...P Pa ag ge e 4 46 6 5 0 Specifications 5 1 Clearance Chart B A C Radial D C Radial...

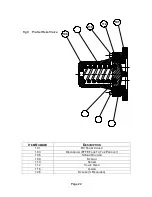

Page 54: ...P Pa ag ge e 5 53 3 5 6 Typical Basic Pump Build RTP20 Shown...

Page 56: ...P Pa ag ge e 5 55 5 5 8 RTPTM Service History Pump Serial No Date Comments...