P

P

a

a

g

g

e

e

1

1

8

8

3.6.1 Additional Routine Maintenance – Atex units.

Grease

-

Check for any signs of lubricant leakage on startup.

-

Check for any signs of overheating.

Low maintenance gearbox, factory filled with EP 00 semi-fluid grease. The

grease should not require replacement during the lifetime of the bearings or

until 14,000 hours of operation.

Oil

-

Check oil levels on startup.

-

Check for any signs of overheating.

-

Change the oil every 6 months or 1500 operating hours, whichever is

the sooner.

For lubricant capacities and grades refer to section 5.3.

After 14000 hours of use, the pump will need a general overhaul and it will

need to be re-certified for use within the Atex environment.

A general overhaul must include a full disassembly of all components and the

following work carried out.

Clean all pump components

Examination of all components for damage/wear

Replacement of all taper roller bearings

Replacement of all elastomeric components

Replacement of all seals, radial seals, and Gamma rings

The general overhaul must be carried out by qualified personnel in a specialist

workshop with the appropriate equipment. Re-certification must then be

carried out.

We highly recommend that the general overhaul is carried out by Wright Flow

Technologies

W

W

A

A

R

R

N

N

I

I

N

N

G

G

W

W

A

A

R

R

N

N

I

I

N

N

G

G

Summary of Contents for Wright Flow Technologies RTP Series

Page 1: ...P Pa ag ge e 0 0 INSTALLATION OPERATION AND MAINTENANCE MANUAL FOR THE RANGE OF PUMPS...

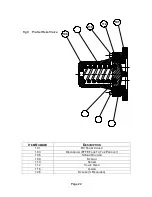

Page 47: ...P Pa ag ge e 4 46 6 5 0 Specifications 5 1 Clearance Chart B A C Radial D C Radial...

Page 54: ...P Pa ag ge e 5 53 3 5 6 Typical Basic Pump Build RTP20 Shown...

Page 56: ...P Pa ag ge e 5 55 5 5 8 RTPTM Service History Pump Serial No Date Comments...