P

P

a

a

g

g

e

e

2

2

5

5

-

Remove product seals, refer to section 4.3.

4.1.2 Gearbox Dismantling

(After Completing 4.1.1).

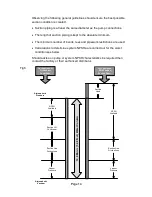

The following procedures assume that the pump has been removed from the

base-plate and that the product seals have been removed (see section 4.3).

-

Remove drain plug (5) and the breather (21). Drain lubricant into a suitable

container and retain if later inspection is required.

-

Remove retaining screws (74), and remove the endplate (70) from the

gearbox (16) utilising the retaining screws (74) in the jacking points

provided, see fig 12. The endplate is located on dowels (60) and is sealed

by the O-ring (3), see fig 11.

-

Remove the cups of the rear bearing (19, see fig 5.6) from the endplate

(70).

-

Remove the bearing pre-load shims (73, see fig 5.6).

The shims (73, see

fig 5.6) may be different for each assembly and therefore should be

kept in their respective positions.

-

Remove rear Lip-seal (11, not shown).

F

F

i

i

g

g

1

1

0

0

F

F

r

r

o

o

n

n

t

t

C

C

o

o

v

v

e

e

r

r

&

&

R

R

o

o

t

t

o

o

r

r

R

R

e

e

m

m

o

o

v

v

a

a

l

l

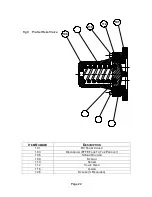

Summary of Contents for Wright Flow Technologies RTP Series

Page 1: ...P Pa ag ge e 0 0 INSTALLATION OPERATION AND MAINTENANCE MANUAL FOR THE RANGE OF PUMPS...

Page 47: ...P Pa ag ge e 4 46 6 5 0 Specifications 5 1 Clearance Chart B A C Radial D C Radial...

Page 54: ...P Pa ag ge e 5 53 3 5 6 Typical Basic Pump Build RTP20 Shown...

Page 56: ...P Pa ag ge e 5 55 5 5 8 RTPTM Service History Pump Serial No Date Comments...