P

P

a

a

g

g

e

e

1

1

5

5

Where motor mounting options are to be installed follow the manufactures

recommended guidelines. However, when installing a pump complete with base and

drive the following guidelines must be observed:

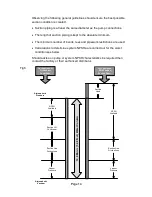

The preferred drive arrangement for any rotary lobe pump is in-line direct coupled.

Flexible couplings must always be incorporated and correctly aligned within the limits

recommended by the coupling manufacturer. To check coupling alignment rotate the

shaft by at least one full revolution and ensure that the shaft rotates smoothly.

Couplings of a non-flexible design must never be used.

Couplings must always be enclosed in a suitable guard to prevent contact with

rotating parts that could result in personal injury. Guards should be of suitable

material, and of sufficiently rigid design to prevent contact with rotating parts

under normal operating conditions.

When installing pump sets in flammable or explosive environments, or for

handling flammable or explosive materials, special consideration must be given

not only to the safety aspects of the drive unit enclosure but also to the materials

used for both the coupling and the guard to eliminate the risk of explosion.

Baseplates must be secured to a flat level surface such that distortion and

misalignment are avoided.

Once baseplates are fastened in position the drive

alignment must be re-checked.

When using electric motor drives, ensure that the electrical supply is compatible

with the drive and controls and that the method of wiring is correct for the type of

starting required by the motor i.e. Direct On-Line, or another similar method.

Ensure all components are correctly grounded.

3.3.2 Installation with CIP Systems.

The RTP

TM

range has been designed to be effectively cleaned by the CIP procedures

recommended for in-place cleaning of the process plant. To assist in maximising the

effectiveness of cleaning within the pump head it is recommended that during the

cleaning cycle a flow rate equivalent to a velocity of 1.5 metres per second; in a pipe of

equal diameter to the rotor case connections is achieved. With a differential pressure of

2 to 3 bar (30 to 45 psi) being developed across the pump head

For applications where maximum drainage of the pump head is required, for example in

the handling of ‘Agri-Foodstuffs’ and/or where CIP is employed, the pump ideally should

be mounted with the rotor case connections in the vertical orientation. A procedure must

be determined to ensure that the pump is effectively cleaned. It is recommended that

this cycle would typically include a combination of some or all of the following: Acidic or

Caustic based Detergents, ‘Sanitisers’, Disinfectants and Water rinses. These must be

appropriate to both the products being handled and the materials of construction of the

pump.

Summary of Contents for Wright Flow Technologies RTP Series

Page 1: ...P Pa ag ge e 0 0 INSTALLATION OPERATION AND MAINTENANCE MANUAL FOR THE RANGE OF PUMPS...

Page 47: ...P Pa ag ge e 4 46 6 5 0 Specifications 5 1 Clearance Chart B A C Radial D C Radial...

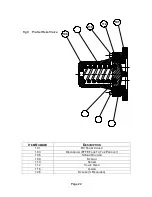

Page 54: ...P Pa ag ge e 5 53 3 5 6 Typical Basic Pump Build RTP20 Shown...

Page 56: ...P Pa ag ge e 5 55 5 5 8 RTPTM Service History Pump Serial No Date Comments...