9

Harrier GTE -

Installation & Servicing

GENERAL

7

2

15

16

10

14

13

7

24

23

7

12

1

7

21

7

13

22

8

7

10

27

7 26

25 7

10

9

11

3

6 7

6

18

20

7

19

13

7

17

4

5

7

7

7

Note.

Minimum static head

requirements with limit thermostat

set at 110ºC (230ºF) is 2.5m.

The example illustrated is intended

as a general guide only. Caradon

Ideal Limited will be pleased to

advise on specific applications.

Design and minimum flow rate

tables are shown Frame 8.

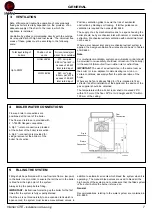

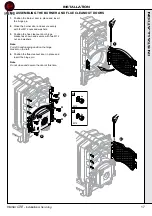

System Design

Recommendations relating to water system design are

contained in BS. 5410: Part 2 and BS. 6880.

System design must allow for adequate internal circulation

within the boiler and sufficient heat release from the boiler

body during and immediately after burner firing. Heating and/

or hot water controls should be interlocked electrically with the

burner, to prevent firing when the system does not demand

heat.

Depending on system design it may be necessary to interrupt

electrical supply to the burner before any mixing valves are

completely closed to the boiler flow. This will dissipate residual

heat. Also a pump overrun of at least 5 minutes is required on

plant shutdown to avoid interference trip out of the overheat

thermostat. If system return temperature remains below 30ºC

for most of the heating period some protection from

condensation is required.

Please contact Caradon Ideal Limited for further information.

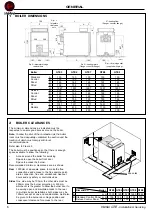

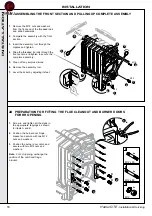

LEGEND

1. Heating outlet

2. Heating return

3. 3 bar safety valve and pressure gauge

4. Flow switch (if necessary)

5. Air separator

6. Automatic venting valve

7. Valve

8. Shunt pump (required for all models)

9. Expansion tank

10. Draining valve

11. Sludge valve

12. Mixing valve

13. Non return valve

14. Heating pump

15. Low-water safety pressure-sensitive switch

16. Sludge decanting pot (particularly recommended for

older heating systems)

17. Independent calorifier

18. Sealed safety unit calibrated to 7 bar with indicator type

discharger

19. Pressure reducer (if mains press >5.5 bar)

20. Domestic cold water inlet

21. Domestic hot water outlet

22. DHW pump

23. DHW circulation pump (optional)

24. DHW circulation loop return

25. Water meter (if any)

26. Water treatment for hard water

27. Heating circuit filling (with disconnecter if required under

applicable regulations).

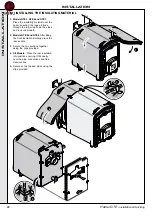

9

SYSTEM DESIGN CONTINUED

Example of Installation

The example below does not cover all the possible cases of

use. It is only aimed at drawing attention to the basic rules

which must be complied with. In all events, comply with

applicable codes of practice and national or local regulations.

Example shows a sealed system with domestic hot water

production via independent calorifiers.

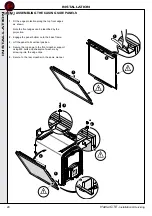

Typical Sealed System Example

A shunt pump sized on the minimum flow rate required MUST

be fitted. Provided adequate heat dissipation can be achieved

at all times the shunt and DHW primary pumps only may run

on during the overrun period allowing the heating pump to be

switched off. This example assumes the DHW primary pump

flow rate required is less than that required for the shunt pump.