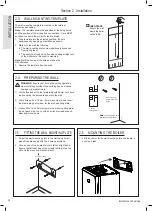

2.14 FITTING THE FLUE SLEEVE

16

17

6

7

8

9

10

11

12

13

14

15

1

2

3

4

5

1

1

6

6

7

Boundary

Boundary

600

300

300 c.

300 b.

600 d.

300

a. < 1000

3

2

1

600

3

4

5

1

2

2000

Opening in adjacent

building

14

3

1

2

300

At an angle to the

boundary

15

2

Parallel to the

boundary

16

Facing the

boundary

8

600

1

300

3

All measurements : mm

2.15 HORIZONTAL FLUE POSITIONS

Flue Sleeve

Flue Pipe

Flue

Terminal

Flexible

Wall

Seal

Wall

Plate

Flue Sleeve Flange

1. Cut hole in wall.

2. Measure wall thickness.

3. Cut sleeve length to match wall thickness & remove

burrs.

4. Grout sleeve into wall with flange on external face.

5. Slide flue pipe into sleeve, checking it is free to slide.

6. Slide Flexible wall seal over flue pipe and push centre

ring up to sleeve flange when cold.

7. Locate wall plate over flexible wall seal and clamp in

place using the raw plug pack.

8. Affix flue terminal.

9. During boiler test check that the flue end is free to

expand and contract with flexible wall seal.

22

Installation and Servicing

FLUE OUTLET

Section 2 - Installation