49

Installation and Servicing

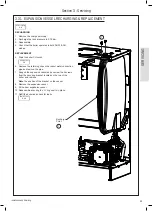

Section 3 - Servicing

SER

VICING

SCAN

for video

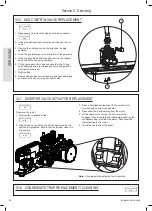

3.22 PRV REPLACEMENT

Refer to Section

3.2

Refer to Section

3.3

Refer to Section

3.3

Refer to Section

3.2

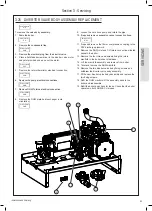

3.23 PUMP AUTOMATIC AIR VENT REPLACEMENT

1. Drain the boiler.

2. Remove the expansion vessel.

3. Firstly, increase access area by disconnecting the 22

mm pipe connection at top of pump manifold and bottom

of heat exchanger and remove pipe.

4. The automatic air vent head is retained in the pump body

with a bayonet connection. The air vent head and float

assembly is removed by turning the head anti-clockwise

(viewed from above) and pulling upwards.

5. Reassemble. Check the air vent head ‘O’ ring seal is

fitted.

6. Check that the air vent cap is loose.

7. Refill the boiler. Check for leaks around the new air vent

joint.

Refer to Section

3.31

Refer to Section

2.16

Refer to Section

2.18

1. Drain the boiler.

2. Remove the trap and rubber pipe.

3. Pull out and remove the clip retaining the PRV.

4. Undo the discharge pipe compression coupling.

5. Lift out the PRV/pipe assembly.

6. Remove the pipe and transfer to the new PRV.

7. Reassemble ensuring the retaining clip is

correctly fitted.

8. Check the operation of the PRV by raising the

water pressure until the valve lifts. This should

occur within 0.3 bar of the preset lift pressure.

9. Check no escape of water occurs except at the

discharge point

10. Release water from the system until the

minimum system design pressure is reached;

1.0 bar if the system is to be pre-pressurised.

3