Page 21 of 28 – Operation and Maintenance Instructions for Offline Filtration Trolley OFT20 & OFT-HV

Document No: E1412015-1488-M-02

HYDAC Pty Ltd - 109-111 Dohertys Road, Altona North, Victoria 3025, Australia

Telephone: +61 (03) 9272 8900 ; Fax: +61 (03) 9369 8912 ; Website:

Changing the Filter Element

Removing Element

The OFT must not be in use.

Remove oil drain plug. Drain oil into container.

Unscrew filter bowl. Drain fluid into a suitable container (The oil must not be put

back into the system unless it is first cleaned!).

Remove filter element from element spigot in filter head (check surface of

element for contamination residue and larger particles; these can indicate

damage to components).

Clean filter bowl and filter head; particular attention must be given to the threads!

Examine filter, especially sealing surfaces, for mechanical damage.

Check O-rings

– and replace if necessary

Fitting new Element

Wet the sealing surfaces and thread on the filter head and bowl/end cover, as

well as the O-ring, with clean operating fluid.

Before fitting a new filter element, check that the designation corresponds to that

of the old element.

Lubricate seal and sealing cone on external diameter with clean operating fluid.

Apply aluminium paste or another suitable lubricant to threads on filter head and

bowl.

Screw in oil drain plug

Check the filter for leakage.

OFT20

Screw in filter bowl fully and tighten to 40 Nm

OFT-HV

Do not torque, screw in filter bowl fully (metal to metal contact) and then

unscrew by one quarter-turn.

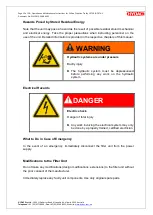

NOTICE

Unsuitable/incorrect filter element

The medium is not filtered

► Use only filter elements with the type code suffix ON or ECON2

(for example:

►

OFT20

200MX 010 ECON2/-B3.5

►

OFT-HV

280 D 010 ON /-QPG1