Filtromat – OF5 C

5 Performing

maintenance

5.1

Changing the Filter Element

TIP

The unit must always be switched off when the filter element is changed.

Pull the power plug!

!

!

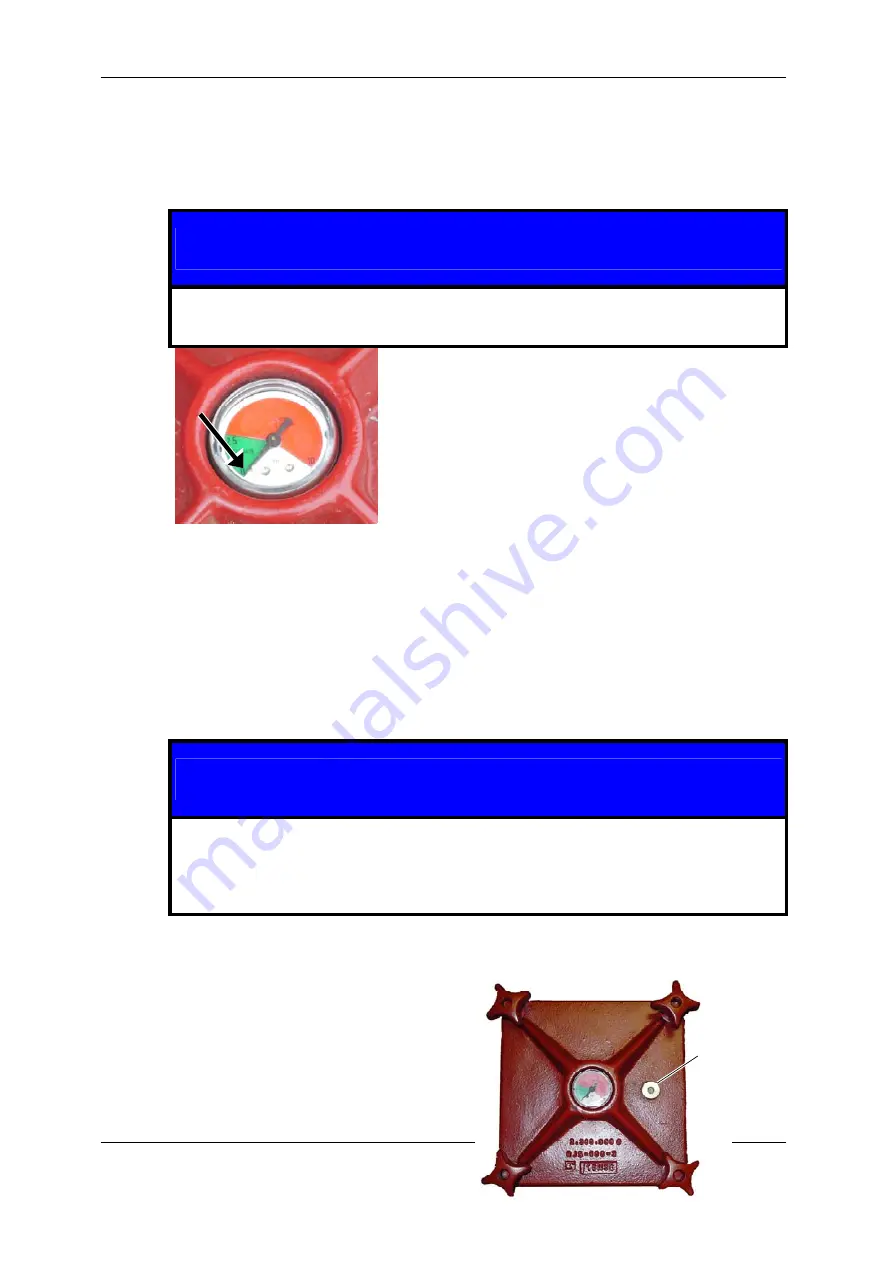

The filter bowl must be depressurized, meaning that

the pressure gauge integrated in the cover plate has

to display "0" bar = the housing is at zero pressure.

If this is not the case, release the pressure by opening the vent plug in the cover

plate.

Depending on the type of installation of the unit, a certain amount of oil can remain

in the filter bowl; this can be drained via the drain plug.

No tools are required to change the filter element. The four toggle screws in the

cover plate are loosened and the eyebolts are pulled down, which pushes the filter

housing cover plate upwards. It can then be removed by hand. Then the filter

element is pulled off the spigot.

TIP

There is a cap on top of the filter element. It seals the bypass valve of the

filter element, and prevents contaminated oil from flooding during a cold

start or when the element is completely clogged. The cap must be replaced

on the new filter element.

Then the new filter element is pushed onto the spigot by turning it slightly. It is

advisable to lubricate the O-ring of the

filter element in the spigot bore as this

will make fitting easier. Replace the

cover, push the star knobs up and

tighten them evenly to secure the cover

to the filter housing.

HYDAC Filtertechnik GmbH

en

Page 21

Now vent the filter housing. While the

pump is running, loosen the vent plug

BeWa OF5C 3160333a en

2008-02-06

(A)