36

A. GENERAL

This vent system will operate with a positive pressure in the pipe. Do not connect vent connectors serving

appliances vented by natural draft into any portion of mechanical draft systems operating under positive

pressure.

Follow the venting instructions below carefully. Failure to do so may result in substantial property

damage, severe personal injury, or death.

1. Install the water heater venting system in accordance with these instructions and with the National Fuel

Gas Code, ANSI Z223.1/NFPA 54, CAN/CGA B149, and/or applicable provisions of local building codes.

2. This water heater is a direct vent appliance and is listed as a Category IV appliance with Underwriters

Laboratories, Inc. VENT AND INTAKE AIR VENT.

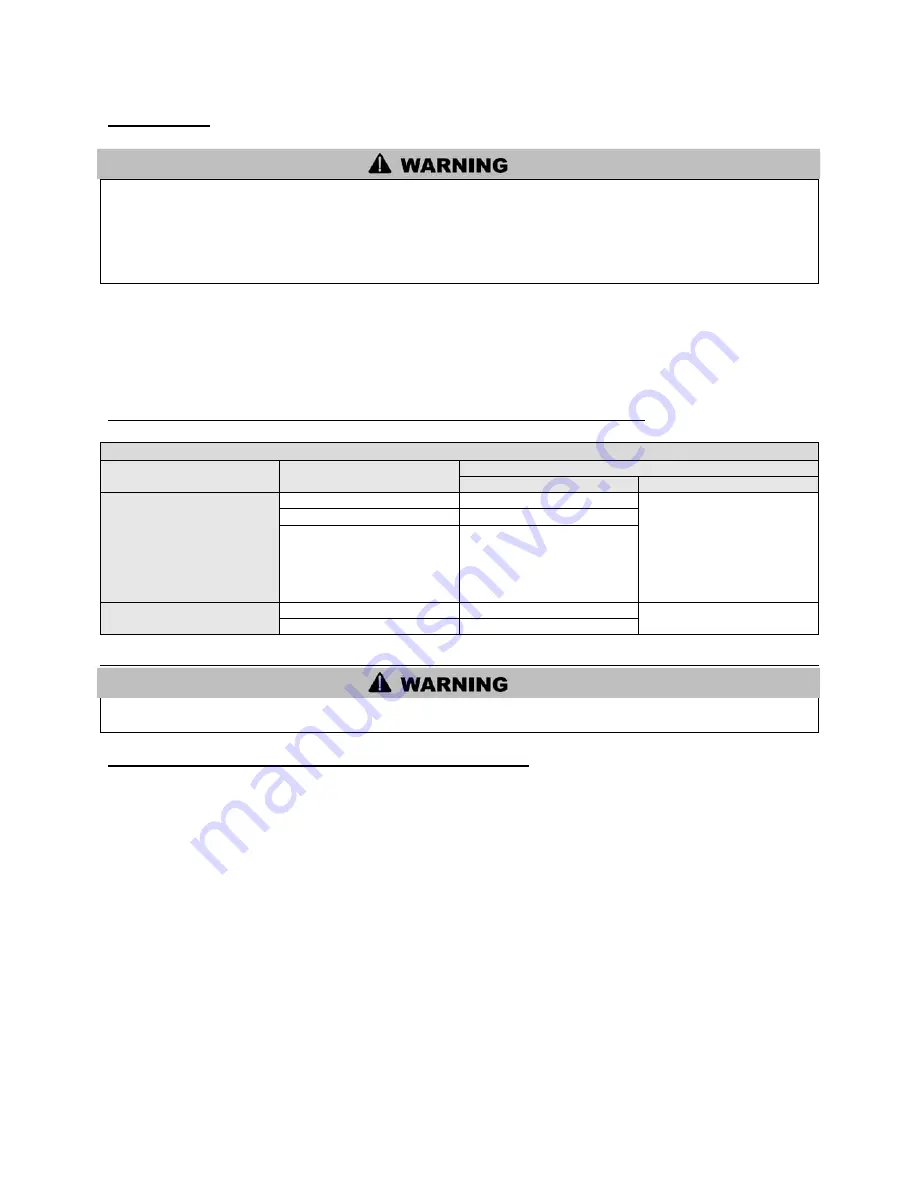

B. APPROVED MATERIALS FOR EXHAUST AND INTAKE AIR VENTS

APPROVED VENTING MATERIAL

Item

Material

Standards for Installation in:

United States

Canada

Vent or air pipe and

fittings

PVC schedule 40/80

ANSI/ASTM D1785

CPVC and PVC venting

must be ULC-S636

Certified. IPEX is an

approved manufacturer in

Canada, supplying vent

material listed to ULC-

S636.

PVC-DWV

ANSI/ASTM D2665

CPVC schedule 40/80

ANSI/ASTM F441

Pipe cement/primer

PVC

ANSI/ASTM D2564

IPEX System 636

Cements & Primers

CPVC

ANSI/ASTM F493

Table 6

Do not use Foam Core Pipe in any portion of the exhaust piping from this water heater. Use of Foam

Core Pipe may result in substantial property damage, severe personal injury, or death.

C. EXHAUST AND INTAKE AIR VENT PIPE LOCATION

1. DETERMINE EXHAUST VENT LOCATION

a. The vent piping for this water heater is approved for zero clearance to combustible

construction.

b. See illustration within this section of clearances for location of exit terminals of direct-vent

venting systems.

c. This water heater vent system shall terminate at least 3 feet (0.9 m) above any forced air intake

located within 10 ft (3 m). Note: this does not apply to the combustion air intake of a direct-vent

appliance.

d. Provide a minimum of 1 foot distance from any door, operable window, or gravity intake into

any building.

e. Provide a minimum of 1 foot clearance from the bottom of the exhaust above the expected

snow accumulation level. Snow removal may be necessary to maintain clearance.

f. Provide 4 feet horizontal clearance from electrical meters, gas meters, gas regulators, relief

equipment, exhaust fans and inlets. In no case shall the exit terminal be above or below the

aforementioned equipment unless the 4 foot horizontal distance is maintained.

g. When adjacent to a public walkway, locate exit terminal at least 7 feet above grade.

Summary of Contents for Versa Hydro PHE130-119

Page 23: ...23 Figure 5 Figure 6 ...

Page 24: ...24 Figure 7 ...

Page 25: ...25 F HYDRONIC PIPING Figure 8 ...

Page 26: ...26 Figure 9 ...

Page 27: ...27 Figure 10 ...

Page 28: ...28 Figure 11 ...

Page 29: ...29 Figure 12 ...

Page 32: ...32 F INTERNAL WIRING Figure 14 Internal connection diagram ...

Page 38: ...38 Figure 17 ...

Page 48: ...48 Figure 25 ...

Page 76: ...76 Figure 29 ...

Page 77: ...77 Figure 30 ...

Page 78: ...78 Figure 31 LP 314 G ...

Page 79: ...79 Figure 32 ...

Page 81: ...81 ...

Page 82: ...82 ...

Page 83: ...83 MAINTENANCE NOTES ...