40

c. You should keep a minimum combined equivalent length between the intake air vent pipe and the

exhaust vent. The minimum combined equivalent length is 32 combined equivalent feet.

d. The size of venting can also be reduced in order to accommodate existing vent sizes. When reducing

down to a 2” vent from a 3” vent, or a 3” vent from a 4” vent, the combined length shall not exceed 100

equivalent feet. Vent reduction must begin at the boiler.

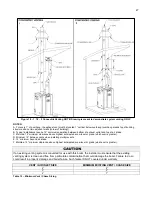

F. LONGER VENT RUNS

The maximum combined equivalent length can be extended by equally increasing the diameter of both the

exhaust and intake air vent pipes. However, transitions should begin a minimum of 32 combined equivalent feet

from the boiler equally on both the intake and exhaust.

The maximum equivalent length for increased diameter vent pipes is 275 feet, which includes the combined 32

feet from the boiler, 16 ft. (inlet) + 16 ft. (exhaust) = 32 ft. combined with transition total of 243 ft. upsize piping for

longer vent runs.

VENT TRANSITION FITTING

SIZE

REDUCING COUPLING

FINAL VENT SIZE

3” Venting

4” x 3”

4”

4” Venting

6” x 4”

6”

6” Venting

8” x 6”

8”

Table 10

Do not exceed the maximum lengths for increased diameter vent pipes. Excessive length could result in appliance

shutdown and property damage.

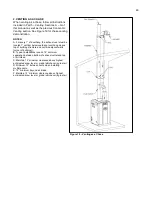

G. EXHAUST VENT AND INTAKE AIR PIPE INSTALLATION

All joints of positive pressure vent systems must be sealed completely to prevent leakage of flue products into

living space. Failure to do so could result in carbon monoxide leakage, property damage, severe personal injury,

or death.

1. Use only solid PVC or CPVC pipe, or a Polypropylene vent system, approved for use with Category IV boilers.

FOAM CORE PIPING IS NOT APPROVED FOR EXHAUST APPLICATIONS. Foam core piping may be used on

air inlet piping

only

.

2. Remove all burrs and debris from joints and fittings.

3. When using PVC or CPVC pipe, all joints must be properly cleaned, primed, and cemented. Use only cement

and primer approved for use with the pipe material. Cement must conform to ASTM D2564 for PVC and ASTM

F493 for CPVC pipe.

NOTE: DO NOT CEMENT POLYPROPYLENE PIPE.

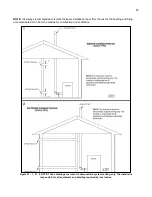

4. Ensure the vent is located where it will not be exposed to prevailing winds.

5. In all roof venting applications, exhaust discharge must point away from the pitch of the roof.

6. To prevent water leakage, install adequate roof flashing where the pipe enters the roof.

Summary of Contents for EL-110

Page 15: ...15 Figure 3 ...

Page 61: ...61 Figure 29 ...

Page 62: ...62 Figure 30 ...

Page 87: ...87 Figure 33 ...

Page 88: ...88 Figure 34 ...

Page 89: ...89 Figure 35 LP 293 A NOTE Parts listed on the following page ...

Page 94: ...94 ...

Page 95: ...95 ...

Page 96: ...96 MAINTENANCE NOTES ...