11b Planning the SAS con

fi

guration

11805

The server must have a SAS HBA with an external connector. Most SAS

RAID controllers do not support Tape Autoloaders.

If your HBA has a different SAS connector than the one on the cable

supplied with the product, see the HP StorageWorks 1/8 G2 Tape

Autoloader QuickSpecs at

http://www.hp.com/go/tape

for a list of

supported cables.

WARNING!

Do not connect the Autoloader to a SAS RAID controller

unless the EBS compatibility matrix shows that the controller is

quali

fi

ed with the Autoloader. The server might not be able to

boot when the Autoloader is connected to a non-supported

SAS RAID controller. See the EBS compatibility matrix at

http://www.hp.com/go/ebs

/.

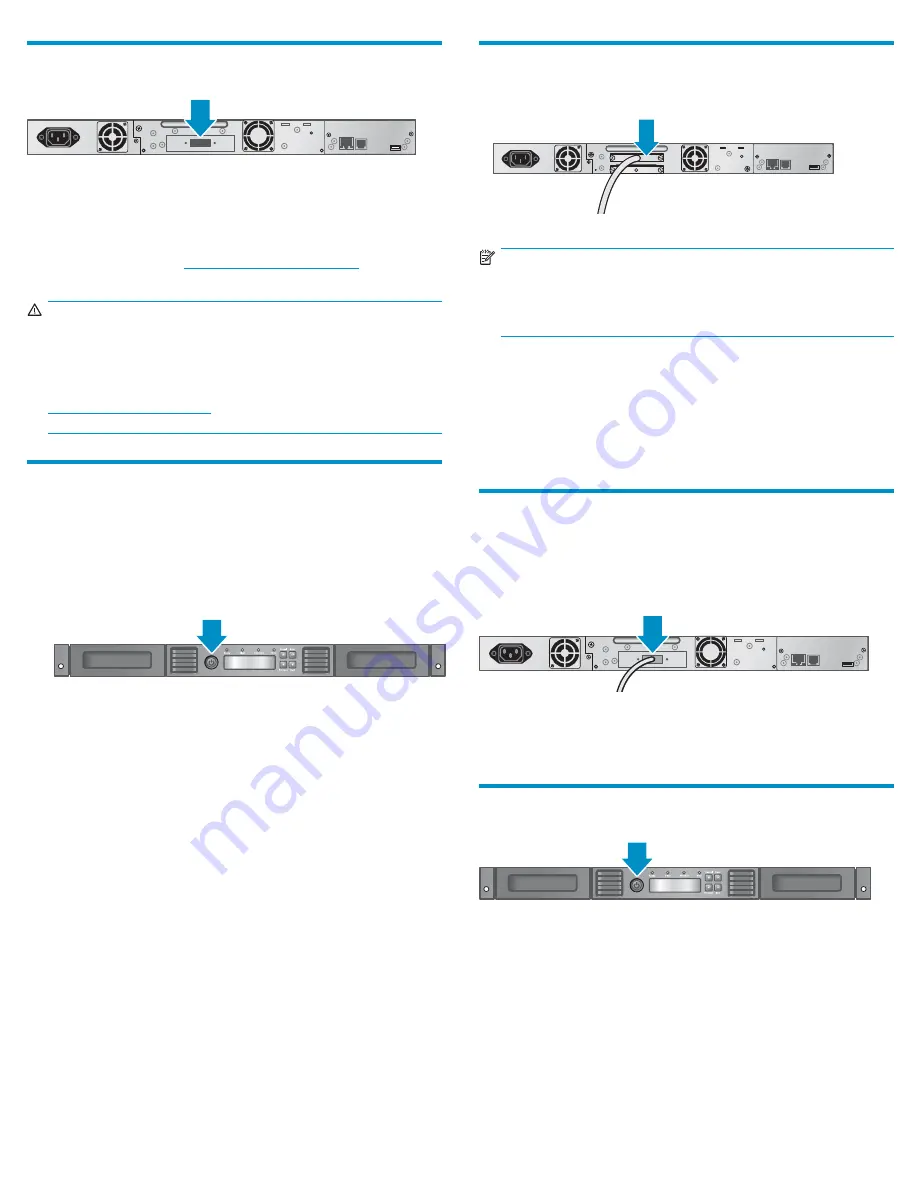

12 Changing the SCSI ID

On a parallel SCSI Autoloader, if you need to change the SCSI ID, do

so before connecting the Autoloader to the host computer.

1.

Plug the power cable into the Autoloader and the power outlet.

2.

Power on the Autoloader by pressing the power button on the front

panel.

11807

3.

On the front panel, press

Enter

.

4.

Press

Next

until the display shows

Configuration

. Press

Enter

.

5.

Press

Next

until the display shows

Change Drive SCSI ID

.

Press

Enter

.

6.

Press

Next

until the display shows the new SCSI ID. Press

Enter

.

13a Connecting a parallel SCSI

Autoloader

11135

NOTE:

A parallel SCSI LTO-3 or LTO-4 tape drive should be the only

device on the bus. A maximum of two LTO-2 tape drives can

be on a single Ultra320 bus.

Attach one end of the parallel SCSI cable to one of the connectors on

the tape drive. Attach the other end of the cable to the host bus adapter

(HBA) or to the connector on the previous device on the SCSI bus.

If the Autoloader is the last or only device on the SCSI bus, attach

a terminator to the remaining SCSI connector on the tape drive.

Otherwise, attach a SCSI cable to the next device on the SCSI bus.

Make sure that the last device on the SCSI bus is properly terminated.

13b Connecting a SAS Autoloader

SAS signal rates require clean connections with a minimum number of

connections between the HBA and the Autoloader. Do not use adapters

or converters between the HBA and the Autoloader. HP recommends a

maximum SAS cable length of six meters.

11804

Attach a mini-SAS connector on the SAS cable to the tape drive. If the

cable has a mini-SAS connector on each end, you may connect either

end to the tape drive. Attach the other connector to the HBA.

14 Powering on the Autoloader

11807

To use the web-based management interface, plug one end of the

Ethernet cable into the Ethernet port on the back of the Autoloader. Plug

the other end of the cable into an Ethernet LAN port.

Plug the power cable into the Autoloader and the power outlet.

Power on the Autoloader using the power button located on the front

panel. Check the LCD screen to make sure the Autoloader is receiving

power.

Power on the host server and all devices you powered off earlier.

Page 7