7 Determining your rack type

11158

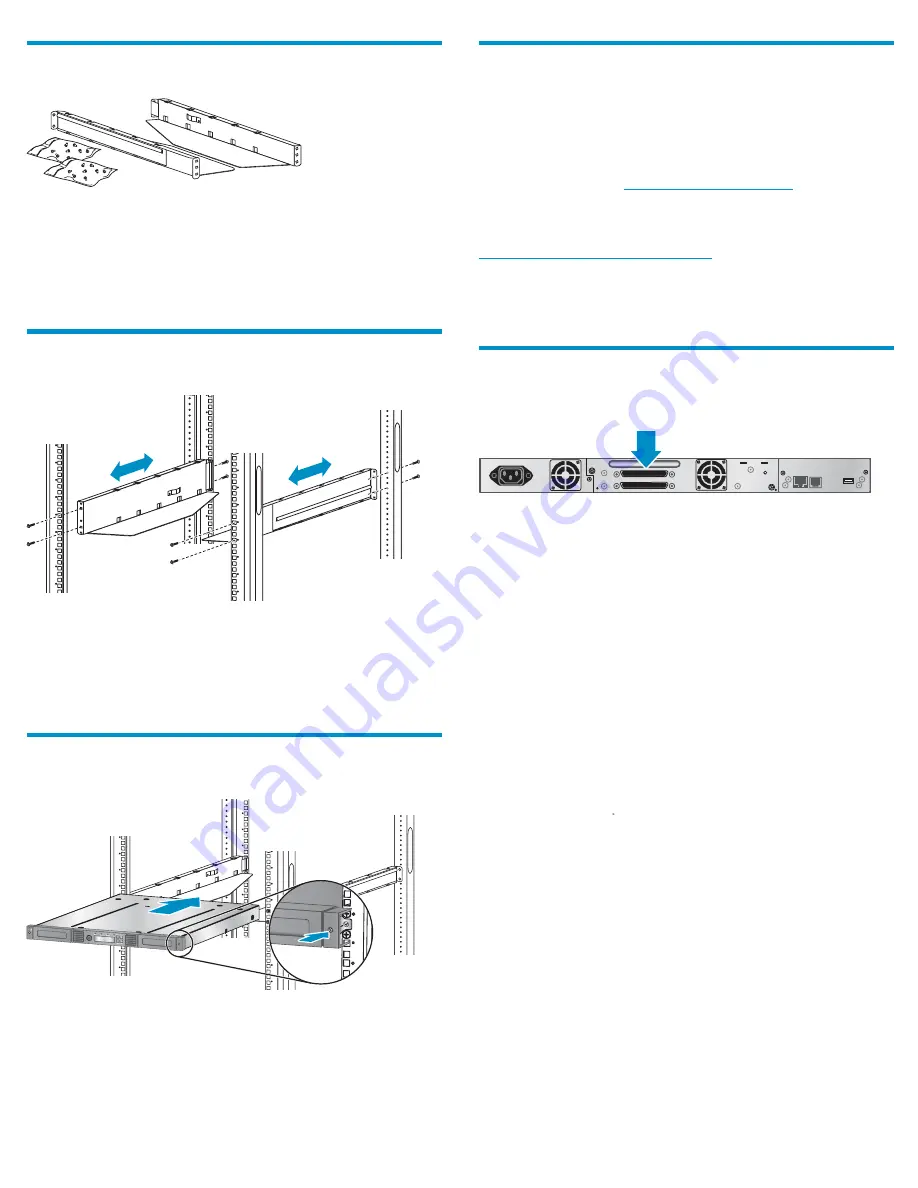

You will need a #2 and #3 Phillips screwdriver, the two rack rails, and

the packet of eight M6 screws appropriate for your rack.

•

The HP System/E rack has 7.1 mm round holes in the rack column.

Choose the bag labeled

HP Rack System/E

.

•

The HP 5000 and 10000 racks have 9.5 mm square holes in the

rack column. Choose the bag labeled

HP Rack 5000, 10000

.

8 Securing the rails to the rack

10779

Using two screws from the packet of screws for your rack and a #3

Phillips screwdriver, secure the front of one rail to the front of the rack.

Expand the rail to the depth of the rack and secure the back of the rail

to the rack. Secure the other rail in a similar fashion.

The front of the rails is straight and the back is angled, as shown.

9 Installing the Autoloader

11157m

Slide the Autoloader onto the rails. Secure the front bezel to the rack

using a #2 Phillips screwdriver placed through the small hole in the

mounting bracket to tighten the captive screws on each side of the

Autoloader.

10 Preparing the host

If necessary, install software, a host bus adapter (HBA), and compatible

drivers in the host computer.

Ensure that your HBA supports multiple LUNs. Verify that multiple LUN

support is enabled for the HBA and operating system.

Check the EBS matrix at

http://www.hp.com/go/ebs

to verify that

your HBA is supported on your host computer and quali

fi

ed with the

Autoloader.

Install the HP Library & Tape Tools diagnostic utility available from

http://www.hp.com/support/TapeTools

to see what devices are

connected to the host, verify the installation, upgrade

fi

rmware, and

to aid in troubleshooting.

HP recommends that the host server be powered off before attaching

new devices.

11a Planning the parallel SCSI

con

fi

guration

11806

If you are unfamiliar with con

fi

guring parallel SCSI devices, read the

parallel SCSI con

fi

guration information in the

User and service guide

on the documentation CD.

Follow these general guidelines when planning the parallel SCSI

con

fi

guration:

•

The LTO-3 and LTO-4 tape drives are Ultra320 parallel SCSI devices.

Only put one LTO-3 or LTO-4 tape drive on an Ultra320 bus. Putting

an LTO-3 or LTO-4 tape drive on a lower performance bus may

degrade its performance. Do not connect an LTO tape drive to an

SE SCSI bus because it will seriously degrade performance.

•

The LTO2 tape drive is an Ultra160 parallel SCSI device. Up to two

LTO-2 tape drives can share an Ultra320 bus or each tape drive

can be on its own Ultra160 bus.

•

Avoid putting the Autoloader on the same parallel SCSI bus as a

disk drive or SE device.

•

The Autoloader’s default SCSI ID is 4.

Page 6