6

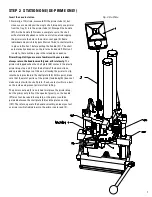

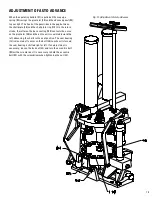

STEP 1: STATION 1A (RESIZE AND DEPRIME)

Place an empty shell in Station 1A, making sure the deprime

punch enters the case mouth and the shell is reasonably

centered under the size die (14) . Pull the operating handle (37) to

the bottom of the stroke . Make sure nothing interferes with the

handle reaching bottom . When the operating handle is pulled,

the platen casting (107) rises until the eccentric arm stop (111)

contacts the base casting (100) . At this point, the shell should

be completely enclosed in the size die (14) and there should be

no gap between the size die ring cap (19) and the platen casting

(107) . When the handle (37) is returned, the de-prime punch

guide (8) pushes the case from the die . The expander (8) is

threaded on the deprime bolt (62) which is forced down by the

clevis link (13) attached to the head casting (7) . The size die (14)

should size the brass head and rim to permit the chambering

of that shell in any firearm .

Properly adjusted, the size die (14)

just contacts the platen casting (107). All other dies are set

from this adjustment point, but are designed with all stations

full.

Interference with the handle (37) can cause light powder

charges or primers not seated properly . The size die (14) and the

size die ring cap (19) must be kept tight at all times .

Fig. 2: Resize and De-Prime