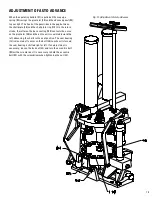

21

BILL OF MATERIAL

Item #

Qty

Part #

Description

1

1

020003

Assembly

1

480032

Movable Lid

1

398415

Panhead Screw

1

480034

Knob

1

480031

Fixed Lid

1

390633

Spring

1

480030

Body

1

480033

Rotor

2

1

050025

Primer Tube Assembly

1

390180

Ferrule

1

290001

Ferrule Tube

3

1

050040

Primer Seater Assembly

1

370047

Spring

1

390069

Screw 10-32 x 1 1/2

1

390068

Primer Pad

1

390065

Well Nut

1

392011

Hex Nut 10-32

1

390086

Locating Pin

4

OBSOLETE

5

1

190003

Measure Casting

6

1

190007

Charge Bar

7

1

190008

Die Head Casting

8

1

190033

Deprime Punch Guide, 12 Ga .

1

190035

Deprime Punch Guide, 20 Ga .

1

190036

Deprime Punch 28 Ga .

1

190037

Deprime Punch 410 Ga .

9

1

190049

Charge Bar Cam

10

OBSOLETE

11

1

380050

Detent Ball & Spring Assembly

12

2

380100

Cam Bearing

13

1

390014

Clevis Link

14

1

390019

Shotshell Size Die Body

15

2

390020

Die Body Lock Nut

16

1

390021

Wad Rod Spring 20 Ga ., 28 Ga . & 410 Ga .

17

OBSOLETE

18

OBS OLETE

19

1

390029

Size Die Ring Cap 12 Ga .

1

390031

Size Die Ring Cap 20 Ga .

1

390032

Size Die Ring Cap 28 Ga .

1

390033

Size Die Ring Cap 410 Ga .

20

1

390038

12/16 ga . Primer Seater Punch

1

390040

20 Ga . Primer Seater Punch

1

390041

28 Ga . Primer Seater Punch

1

392076

410 Ga . Primer Seater Punch

21

OBSOLETE

22

OBSOLETE

23

3

390087

9/16-18 Lock Nut

24

2

390089

1/4-20 He x Lock Nut

25

2

390092

1/2-20 x 5/8" Bolt

26

3

390093

Clevis & Cam Bolt

27

4

390098

Poly Hopper Rivet

28

2

390096

1/2-20 Jam Nut

29

3

390097

Lock Nut 3/8-16

390178

Lock Nut 28/410 1/4-20

30

2

390100

Guide Post

31

4

390101

Guide Post Bolt

32

1

398120

Pivot Shaft

33

2

398121

Eccentric Arm

34

2

390105

Drive Link

35

2

390106

Drive Link Roll Pin

36

2

390107

Platen Drive Bolt

37

1

390657

Operating Handle

38

1

390027

5/8-18 Jam Nut

39

1

390119

Bearing Pin

40

1

390124

Clevis Rod

41

2

390125

Clevis Rod Bushing

42

1

390126

Primer Feed Body

43

1

390127

Measure Plate Hold-Down Screw

44

1

390128

Measure Plate Hold-Down Washer

45

1

390129

12 Ga . Shell Plate

1

390141

20 Ga . Shell Plate

1

390147

28 Ga . Shell Plate

1

392078

410 Ga . Shell Plate

Item #

Qty

Part #

Description

46

1

390132

12/16 ga . Powder Drop Tube

1

390144

20 Ga . Powder Drop Tube

1

390156

410/28 Ga . Powder Drop Tube

47

1

390133

12/16 ga . Shot Drop Tube

1

390145

20 Ga . Shot Drop Tube

1

390157

410/28 Ga . Shot Drop Tube

47A

1

390155

Deprime Punch 20 Ga ., 28 Ga ., & 410 Ga .

1

390134

Deprime Punch 12 Ga .

48

1

390146

12/16 Ga . Wad Ram

1

390158

20 Ga ., 28 Ga ., Wad Ram

1

390152

410 Ga . Wad Ram

49

1

390179

Shell Plate Washer

50

1

390186

Clevis Rod Bolt

51

2

390187

Set Screw

52

1

390188

Measure Attaching Bolt

53

3

390095

10-32 x 3/8 Screw (12 Ga .,20 Ga . & 28 Ga .)

53

1

390190

Set Screw 10-32 5/8 (410 Ga . Qty . 3)

54

2

390196

Split Washer 3/8

55

1

390198

Crimp Die Spring

1

392080

410/28 Ga . Crimp Die Spring

56

2

390201

Bearing Pin E Clip 7/32

57

1

390202

Crimp Die Bushing 12 Ga ., & 20 Ga .

390203

410/28 Ga . Crimp Die Bushing

58

1

390204

Crimp Plunger 12 ga .

390206

Crimp Plunger 20 Ga .

390207

Crimp Plunger 28 Ga .

390208

Crimp Plunger 410 Ga .

59

1

390212

12 Ga . 2 3/4" Crimp Die Body

390213

12 Ga . 3" Crimp Die Body

390215

20 Ga . 2 3/4" Crimp Die Body

390216

20 Ga . 3" Crimp Die Body

390217

28 Ga . Crimp Die Body

392075

410 Ga . Crimp Die Body

60

1

390633

Primer Tube Filler Spring

61

2

390066

Push Nut

62

1

392053

Size Die Eject Bolt

63

1

392054

Shell Retainer Spring

64

2

392055

3/8 Flat Washer

65

2

392101

Crimp Starter Rod

66

2

392102

Crimp Starter Bushing

67

1

392103

Measure Plate

68

1

392104

Measure Plate Spacer

69

1

392105

Powder Slide

70

1

392106

Shot Rotor Slide

71

1

392107

Powder Slide Spring

72

1

392108

Shot Rotor Slide Spring

73

4

392109

Roll Pin 1/8 X 1/4

74

2

480001

Measure Seals

75

1

480003

Plastic Handle Ball

76

1

480006

Primer Catcher

77

1

480007

12 Ga . Spring Finger

480009

20 Ga . Spring Finger

480010

28 Ga . Spring Finger

480011

410 Ga . Spring Finger

78

1

480028

Stop Unit

79

See Accessories

80

2

490002

Shot/Powder Hopper Tube

81

2

490003

Hopper Cap

82

1

490500

12 Ga . 8pt . Crimp Starter

490501

12 Ga . 6pt . Crimp Starter

490313

12 Ga . Paper Crimp Starter

490503

20 Ga . 8pt . Crimp Starter

490504

20 Ga . 6pt . Crimp Starter

490319

20 Ga . Paper Crimp Starter

490509

28 Ga . 6pt . Crimp Starter

490321

28Ga . Paper Crimper Starter

490511

410 Ga . 6pt . Crimp Starter

490323

410 Ga . Paper Crimp Starter

490512

10 Ga . 6pt . Crimp Starter

(continued on page 22)